40

Installation and Maintenance Manual, Compact CA

Maintenance

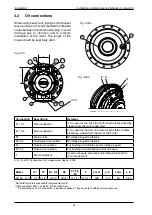

D3

F1

Motor

If the motor is to be stored stationary for a

longer period than about 1 month, it must be

protected from internal rust. This can be done

as follows:

1. Mix anti-rust additive with the hydraulic

fluid of the system. Use 5% of Rust Veto

Concentrate (manufactured by E F

Houghton & Co, Philadelphia, USA). This

additive gives rust protection for up to

about 1 year, after which time the motor

must be turned a few revolutions.

. If no additives are used, the motor must

be regularly turned a few revolutions.

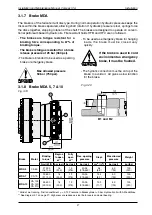

3. If it is not possible to turn the motor, plug

all connections, open drain outlet D1 or D

on the port end housing (or if the motor is

mounted vertically, Flushing connection F1

on the shaft end housing) and fill the motor

with hydraulic fluid.(See Fig. 4.3 and 4.3a).

Fig. 4.3

Fig. 4.3a

D

D1

4.4 Periodic maintenance

When a hydraulic system has been in service

for some time, it must undergo periodic

maintenance and servicing at intervals which

depend on the equipment and the type of

duty.

This periodic maintenance must include the

following operations:

- Check the hydraulic system for leakage.

Tighten the screws, replace faulty seals and

keep the drive clean.

- Inspect and clean all air, oil and magnetic

filters; replace all filter cartridges for which

a filter clogged indication has been given;

inspect tank, pump, filters etc. and clean if

necessary.

Rpl

= Replacement

Insp

= Inspection

Ctrl

= Control of braking torque

- Check the pressure and temperature of the

hydraulic fluid and carry out routine opera-

tions. Adjust valves etc. if necessary.

- Check the hydraulic fluid; see the Section

headed "Oil".

- Check that no dirt or other contaminations

enter the system during inspection.Check

that the outside of the hydraulic motor in an

installation is kept free of dirt; thus leakage

and faults will be detected earlier.

- We recommend that a running log be kept

and that planned inspections are carried out

at set intervals.

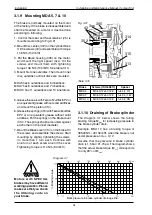

- Maintenance checks and operations are as

follows:

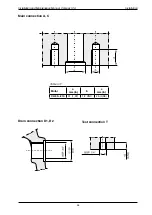

Maintenance chart

In operation

Oil

filters

Oil

Braking

equipment

Torque

arm

After the first

100 hours

Rpl.

Insp.

Insp.

After 3 months

or 500 hours

Rpl.

Insp.

Once every 6

months

Rpl.

Insp.

Insp.

Insp.

Once every 1

months

Ctrl