1

Installation and Maintenance Manual, Compact CA

Motor

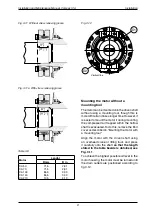

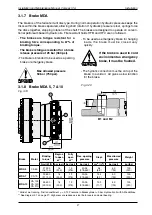

CA50/70

CA100/140

CA210

Tooth profile

and bottom

form

DIN 5480

DIN 5480

DIN 5480

Tolerance

8f

8f

8f

Guide

Back

Back

Back

Pressure angle

30°

30°

30°

Module

5

5

5

Number of

teeth

6

8

Pitch diameter

Ø 110

Ø 130

Ø 140

Minor diameter

Ø 109

Ø 19

Ø 139

Major diameter

Ø 119

Ø139

Ø 149

Measure over

measuring pins

19,781

149,908

159,961

Diameter of

measuring pins

Ø 10

Ø 10

Ø 10

Addendum

modification

X M

+,5

+,5

+,5

Spline

Thread for mounting tool

0

-1,6

0

-0,50

-0,083

-0,147

-0,085

-0,150

0

-1,6

0

-0,0

0

-0,50

0

-1,6

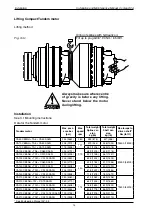

Table 3.3

-0,085

-0,150

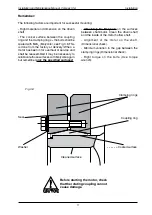

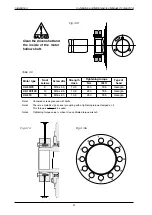

The splines shall be lubricated with hydraulic

oil, or filled with transmission oil from the

connected gearbox. To avoid wear in the

splines, the installation must be within the

specified tolerances in fig. 3.3. If there is no

radial or axial force on the shaft, the shaft can

be oiled only.

For production of the shaft, see 78 30,

78 31, 78 3, 78 33, 78 34,

78 35, 78 36, 78 38 and 78 39.

For control of spline see table 3.3.

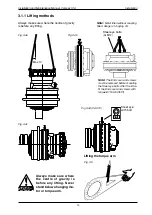

To make it easier to mount the motor on

the driven shaft end or to remove the motor

from the shaft it is recommended that a hole

(Table 3.4) should be drilled and tapped in the

centre of the shaft for a mounting tool; see

3.1.4 "Mounting the motor onto the driven

shaft", and 3.1.5 "Removing the motor from

the driven shaft".

The tool has both a UNC thread and a metric

thread, so that the hole can be drilled and

tapped to conform to one of the two alternatives

given in table 3.4.

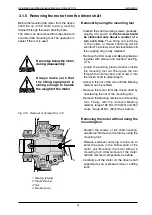

Installation

Fig 3.3

Table 3.4 Alternative thread (Fig.3.1 and 3.2)

Unidirectional drives

Bidirectional drives

Steel with yield strength

Rel

mm

= 450 N/mm

Steel with yield strength

Rel

mm

= 700 N/mm

CA 50-210

D

E

F

G

M0

>17 (0,67)

5 (0,98)

50 (1,97)

UNC 5/8"

>13,5 (0,53)

(0,87)

30 (1,18)

(0.008)

(0.006)