5

Installation and Maintenance Manual, Compact CA

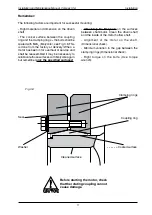

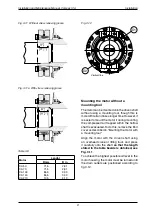

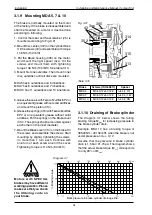

3.1.5 Removing the motor from the driven shaft

- Slacken the shaft coupling screws gradually;

see Fig. 3.14 and 3.14a.

Each screw should

be slackened only about a quarter of a

turn each time. Thus tilting and jamming

of the collars or thread stretching will be

avoided. The screws must be slackened until

the coupling ring is fully released.

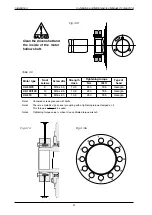

- Remove the End cover and Bearing retainer

together with screws and washers; see Fig.

3.15.

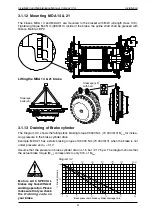

- Locate the existing plastic washer outside

the mounting tool nut.Then pass the tool

through the centre shaft, and screw it into

the driven shaft to stated depth.

- Screw in the nut of the tool until the Bearing

retainer can be refitted.

- Remove the motor from the driven shaft by

unscrewing the nut of the mounting tool.

- Remove the Bearing retainer and mounting

tool. Finally, refit the removed Bearing

retainer, torque 136 Nm (100 lbf·ft) and End

cover, torque 81 Nm (59 lbf·ft) as before.

Before dismounting the motor from the driven

shaft the oil in the motor housing must be

drained through the lower draining hole.

The motor can be removed from the shaft with

or without the mounting tool. The operation is

easier if the tool is used.

Removal by using the mounting tool

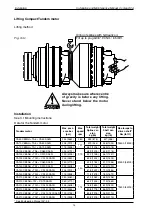

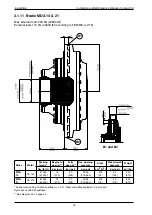

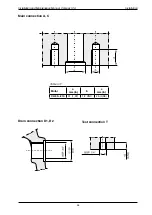

Fig. 3.15 Removal of Compact 50...210

2; Plastic Washer

4; Mounting tool

3; Nut

1; Bearing retainer

4

3

1

Installation

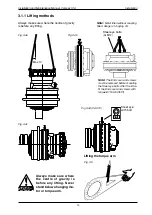

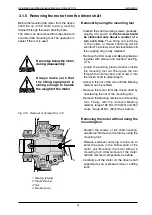

Always make sure that

the lifting equipment is

strong enough to handle

the weight of the motor

Never stay below the motor

during disassembly

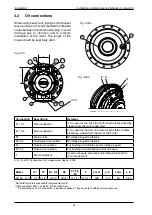

Removing the motor without using the

mounting tool

- Slacken the screws of the shaft coupling,

see above "Removal of motors by using the

mounting tool".

- Remove endcover and plug to allow air to

enter the space in the hollow shaft of the

motor; see “Mounting the motor without a

mounting tool“. After removal of the motor,

refit the removed components as before.

- Carefully pull the motor off the driven shaft

supported by an overhead crane or a lifting

truck.