41

Installation and Maintenance Manual, Compact CA

All hydraulic fluids are affected

differently. Obtain the advice of

your oil supplier or by nearest

Hägglunds representative.

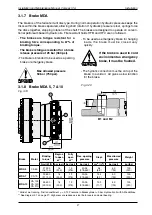

Filters must be changed after the first 100

working hours and the second change is to

be carried out after 3 months or 500 working

hours whichever is earlier. They must then be

changed at regular intervals of 6 months or

4000 working hours.

Oil

(Se also .3)

Analysis

It is recommended that the oil should be

analysed every 6 months. The analysis should

cover viscosity, oxidation, water content,

additives and contamination.

Most oil suppliers are equipped to analyse the

state of the oil and to recommend appropriate

action. The oil must be replaced immediately if

the analysis shows that it is exhausted.

Viscosity

Many hydraulic oils become thinner with

increasing use, and this means poorer

lubrication. The viscosity of the oil in service

must never fall below the minimum recom-

mended viscosity.

Oxidation

Hydraulic oil oxidizes with time of use and

temperature. This is indicated by changes

in colour and smell, increased acidity or

the formation of sludge in the tank. The rate

of oxidation increases rapidly at surface

temperatures above 60°C (140°F), and the oil

should then be checked more often.

The oxidation process increases the acidity of

the fluid; the acidity is stated in terms of the

"neutralisation number". Typical oxidation is

slow initially and increases rapidly later.

A sharp increase (by a factor of and 3) in the

neutralisation number between inspections is

a signal that the oil has oxidized too much and

should be replaced immediately.

Filters

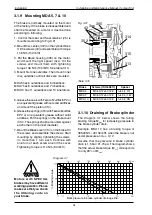

Contamination of the oil by water can be

detected by sampling from the bottom of the

tank. Most hydraulic oils repel the water, which

then collects at the bottom of the tank. This

water must be drained off at regular intervals.

Certain types of transmission oils and engine

oils emulsify the water; this can be detected

by coatings on filter cartridges or a change in

the colour of the oil. Obtain the advice of your

oil supplier in such cases.

Degree of contamination

Heavy contamination of the oil causes

increased wear of the hydraulic system

components. The cause of the contamination

must be immediately investigated and re-

medied.

Water content

Maintenance

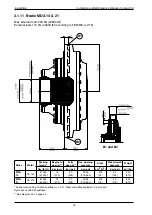

4.5 Oil inspection

Purpose

The purpose to take an oil sample is to check

the condition of the oil.

With scheduled oil analysis, wear products

can be identified and corrective action can be

taken before failure occurs. Oil analysis can

indicate when an oil change is required, point

out shortcomings in maintenance and keep

repair cost to a minimum. Using oil analysis

can create a “window of opportunity”, allowing

the user to schedule re-fittings or overhauls,

maintenance or repairs, thus saving money on

equipment repairs and downtime.

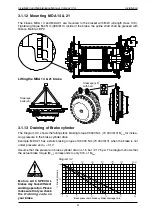

The most used method is to take samples in a

special bottle and send it to a fluid laboratory

for an analysis and from the laboratory you get

a report, which follow a specific international

standard.