38

Installation and Maintenance Manual, Compact CA

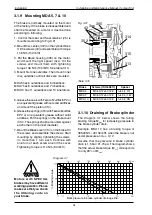

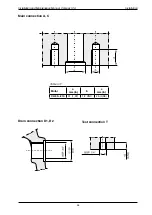

D

D1

C1

A1

F3

F4

Maintenance

d

e

4.

OPERATING INSTRUCTIONS

4.1

Storage

The motor is delivered with internal protection in the form of an oil film and external protection in

the form of an anti-rust film. This provides sufficient protection for indoor storage in normal tem-

peratures for about 1 months.

Note: the anti-rust protection must be touched-up after transport and handling.

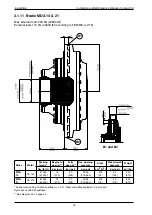

If the motor is stored for more than 3 months in uncontrolled environment or more than 1 months

in controlled environment, it must be filled with oil and positioned as shown in Fig. 3.7.

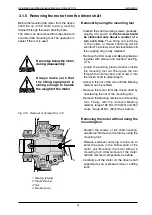

Fig. 4.1a

For calculation of required flushing, please

contact your Hägglunds representative.The

flushing oil shall be drained in the normal

drainline. See 3...

Connect the input line for flushing in the lowest

flushing F3 or F4, see fig. 4.1

For shaft pointing downwards, input line shall

be D3, see fig. 3.9. When there is risk for

pressurespikes in motorcase, input line D3 or

D is recommended.

Flushing of motor case

To avoid high temperature in the motor case

the heat must be removed, because high tem-

perature gives lower viscosity and that gives

reduction in basic rating life/service life. Low

viscosity also means reduced permitted output

power from the motor.

- For continuous duty in applications with an

ambient temperature of +0°C (68°F), the

motor case must be flushed when the output

power exceeds the values shown beside.

Max. power without flushing

CA 50/70

60 kW

(80 hp)

CA 100/140/10

10 kW (160 hp)

Vertical line

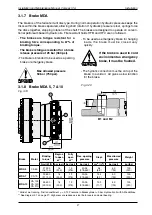

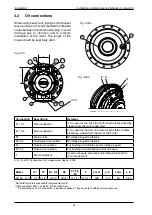

3.2.3 Flushing

Flushing inlet for

mod. 0. Connec-

tion G1/4". Max

allowed flushing

0 litres/min (5.5

gal./min)

Fig. 4.1b

G 1/4" Flushing connection

F3, F4