Habasit Italiana S.p.A.

Vittorio Veneto 31029 (TV)

Tel.: ++39(0)438.9113

Fax. ++39(0)438.200545

Regulating Unit PMR-07

Author:

A.T. / KM

CONNECTIONS

Edition: 04/2006

Page

F-7

Replaces: 10/2005

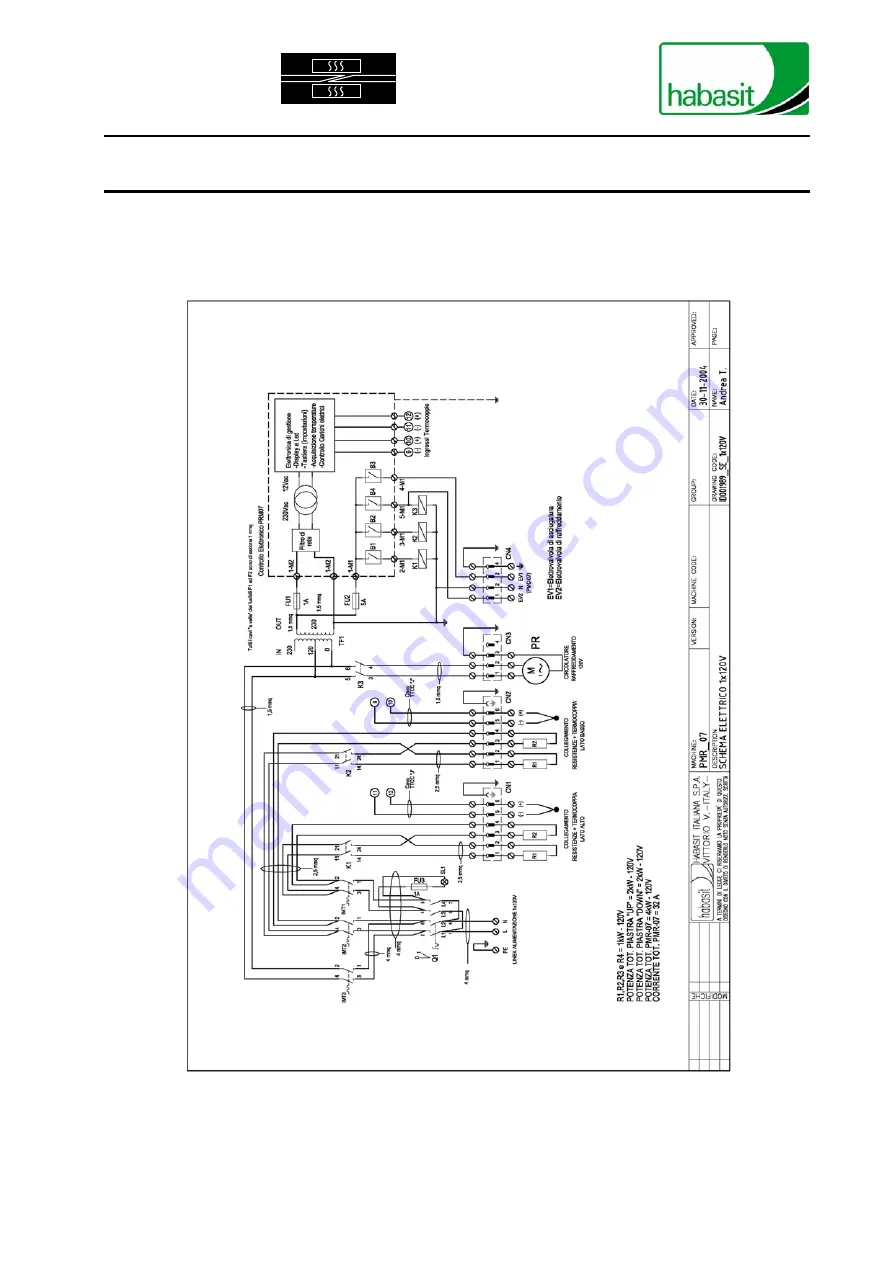

F.3.2

C

IRCUIT DIAGRAM OF

PMR-07

-

120V

F

IGURE

11

-

E

LECTRIC LAYOUT

PMR-07

-

120V

Regulating Unit PMR-07