GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Keine Haftung für Druckfehler. Technische Änderungen vorbehalten! Liability for printing errors excluded. We reserve the right to introduce modifications. Sous réserve de

modifications! Nous ne sommes pas responsables d’éventuelles erreurs d’impression! #0058129

08/2007

17

•

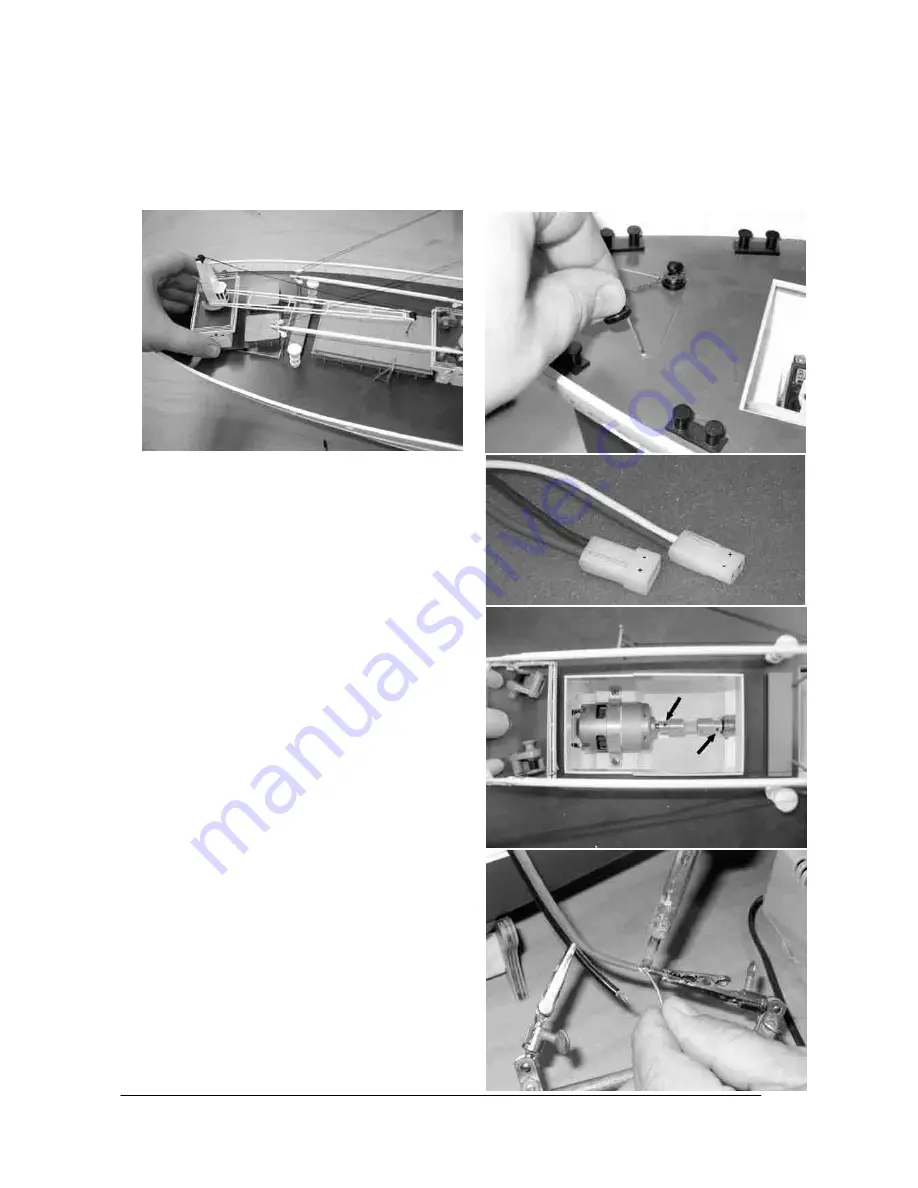

The loading hatches on the ship’s centreline can also be removed, although these are primarily required

only for checking the position of the batteries and maintaining the power system. The long loading hatch

at the stern is also removable, but only after dismantling the derricks located above it. However, this

hatch is not generally required for assembling and operating the model. The rear superstructure

(supporting the small crane) provides access to the rudder servo, and this can also be lifted off. The

hatch above the rudder shaft can be removed after withdrawing the two winches; this gives access to

the rudder system for maintenance.

•

Solder G2 plugs to the wires attached to the motor,

referring to the wiring diagram on page 10 (+ is red,

- is black). Ensure that the motor spins in the

correct direction: when the batteries are connected,

the propeller should rotate in such a way that the

model would be propelled forward.

NOTE

: the

raised lug on the plastic housing of all G2

connectors should always be the positive terminal

(red wire). If you keep consistently to this principle,

your batteries and speed controllers will be

interchangeable, and the system will be protected

against accidental reversed polarity. To make it

easier to solder the plug, it is advisable to use one

of the following methods, as this will reduce the

likelihood of damaging the model with the soldering

iron.

METHOD 1:

remove the motor from the model

by first undoing the grubscrew in the propeller and

withdrawing it. Undo the motor screws in the

retaining bar (don’t remove them completely!) and

withdraw the motor complete with the propeller

shaft. The motor can later be re-installed simply by

reversing the above sequence of operations. Check

that the grubscrews in the shaft coupling are tight

when you do this.

METHOD 2:

use a “third hand” (a

special positionable part-holding tool) to hold the

plug, and use the soldering iron directly inside the

hull (see photo).