26 / 60

Artikel-Nr. 15 513 50 c

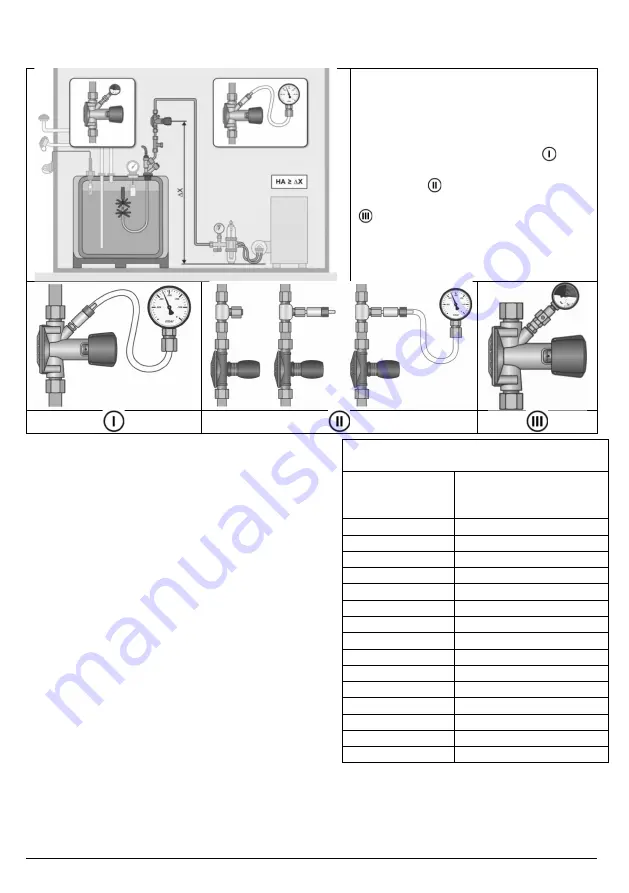

Figure 5: Version 2:

Simulation of a line rupture through pressure measurement on the

anti-siphon device

The function check is also possible

without removing the distiller hose line

by measuring the vacuum directly

after the diaphragm-controlled anti-

siphon device. Either you directly use

the factory-set test connection or

you equip the suction line with a test

connection .

A pressure gauge, e.g. a manometer

which is subject to test equipment

monitoring, is to be used for the

pressure measurement.

For this functional check it is necessary to comply

with the following steps:

Hydrostatic pressure of the fuel oil

column depending on the height

Connect the pressure gauge.

1. Successfully complete leak testing with test

vacuum -300mbar.

2. In the event of the subsequent assembly of a

test connection in the oil line, the actual

hydrostatic pressure of the fuel oil column also

has to be calculated po,g at the height of ∆X+

instead of the height ∆X.

3. Refer to the table for the hydrostatic pressure

of fuel oil column

p

o,g

.

4. Calculate the minimum permitted closing

pressure of the safety equipment against

siphoning

p

o,

= (

p

o,g

+ 5) • (-1) [mbar].]

Height ∆X

(∆X+)

in [mm]

p

o,g

in [mbar]

fuel oil EL

0.50

42

0.75

63

1.00

84

1.25

10

1.50

12

1.75

14

2.00

16

2.25

19

2.50

21

2.75

232

3.00

253

3.25

274

3.50

295

3.75

317

4.00

337

Comment 1:

The closing pressure of the diaphragm-controlled anti-siphon device must always be above the

value of the hydrostatic pressure of fuel oil column p

o,g

and is set in the factory. The safety

allowance selected for this purpose totals 5mbar acc. EN 12514.