4 - 20

Z-30/20N • Z-30/20N RJ • Z-34/22 • Z-34/22N

Part No. 139378

June 2011

Section 4 • Repair Procedures

REV A

PRIMARY BOOM COMPONENTS

5 Remove the primary boom extend drive limit

switch from the pivot end of the primary boom.

Do not disconnect the wiring.

6 Remove the retaining fastener from the master

cylinder rod-end pivot pin. Use a soft metal drift

to remove the pin.

7 Manually retract the master cylinder and push it

toward the platform end of the boom to obtain

enough clearance for extension cylinder

removal.

8 Tag, disconnect and plug the extension cylinder

hydraulic hoses. Cap the fittings on the

cylinder.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to squirt

or spray.

9 Remove the retaining fastener from the

extension cylinder barrel-end pivot pin. Use a

soft metal drift to remove the pin.

10 Carefully pull out and properly support the

extension cylinder from the primary boom with

a lifting strap from an overhead crane.

Crushing hazard. The cylinder

could fall if not properly supported

when it is pulled out of the

extension tube.

Note: To make installation of the extension cylinder

easier, be sure that the cylinder rod is extended

3 to 4 feet / 1 m.

Note: During removal, the overhead crane strap will

need to be carefully adjusted for proper balancing.

4-5

Platform Leveling Master

Cylinder

The platform leveling master cylinder acts as a

pump for the slave cylinder. It is part of the closed-

loop hydraulic circuit that keeps the platform level

through the entire range of primary boom motion.

The platform leveling master cylinder is located

inside the upper mid-pivot at the pivot end of the

primary boom.

How to Remove the Platform

Leveling Master Cylinder

Bodily injury hazard. This

procedure requires specific repair

skills, lifting equipment and a

suitable workshop. Attempting this

procedure without these skills and

tools could result in death or

serious injury and significant

component damage. Dealer

service is strongly recommended.

Note: When removing a hose assembly or fitting,

the O-ring on the fitting and/or hose end must be

replaced and then torqued to specification during

installation. Refer to Section 2,

Hydraulic Hose and

Fitting Torque Specifications.

Note: Before cylinder removal is considered, bleed

the cylinder to be sure that there is no air in the

closed loop. See 2-1,

How to Bleed the Slave

Cylinder.

Содержание Z-30/20N

Страница 1: ......

Страница 4: ...Z 30 20N Z 30 20N RJ Z 34 22 Z 34 22N PartNo 139378 June2011 iv This page intentionally left blank...

Страница 148: ...6 46 June2011 Section 6 Schematics 6 45 Power Cable Wiring Diagram...

Страница 149: ...6 47 Section 6 Schematics June2011 6 48 Drive Contactor Panel Wiring Diagram...

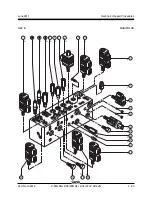

Страница 152: ...6 50 June2011 Section 6 Schematics Manifold and Limit Switch Wiring Diagram 6 49...

Страница 153: ...6 51 Section 6 Schematics June2011 6 52 LVI BCI Option Wiring Diagram...

Страница 156: ...6 54 June2011 Section 6 Schematics 6 53 Charger Interlock Option...

Страница 157: ...6 55 Section 6 Schematics June2011 6 56 CTE Option CE Models...

Страница 160: ...6 58 June2011 Section 6 Schematics Hydraulic Schematic 6 57...