3 - 20

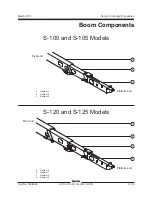

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

S-105 and S-125 models:

12 Remove the pin retaining fasteners from the jib

boom and jib boom leveling arms to platform

rotator pivot pins. Do not remove the pins.

13 Support the jib boom leveling arms with a

suitable lifting device.

14 Use a soft metal drift to remove both pins and

remove the platform rotator from the machine.

Crushing hazard. The jib boom

leveling arms may fall if they are

not properly supported when the

jib boom leveling arm pivot pin is

removed.

Component damage hazard. The

platform angle sensor is a very

sensitive instrument. It can be

damaged internally if the platform

rotator is dropped or sustains

any physical shock, even if the

damage is not visible.

How to Bleed the Platform

Rotator

Note: Do not start the engine. Use auxiliary power

for all machine functions in this procedure.

S-105

(Before serial number 251)

and

S-125 models

(Before serial number 999)

:

1 At the ground controls, simultaneously hold the

auxiliary power button and the platform rotate

right button until the platform is fully rotated to

the right.

PLATFORM COMPONENTS

2 Connect a clear hose to the top bleed valve.

Place the other end of the hose in a container

to collect any drainage. Secure the container to

the boom.

3 Slowly open the top bleed valve on the rotator.

Do not remove the bleed valve from the

platform rotator.

Bodily injury hazard. Spraying

hydraulic oil can penetrate and

burn skin. Loosen hydraulic

connections very slowly to allow

the oil pressure to dissipate

gradually. Do not allow oil to squirt

or spray.

a

top bleed valve

b

bottom bleed valve

c

clear hose

d container

c

a

b

d

Содержание S-100

Страница 224: ...4 38 S 100 S 105 S 120 S 125 Part No 1268494 March 2017 Section 4 Diagnostic Codes This page intentionally left blank ...

Страница 244: ...March 2017 Section 5 Schematics 5 20 S 100 S 105 S 120 S 125 Part No 1268494 This page intentionally left blank ...

Страница 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Страница 253: ...Section 6 Schematics March 2017 6 29 Engine Options Perkins S 100 105 120 125 from serial number 874 6 30 ...

Страница 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Страница 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Страница 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Страница 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Страница 267: ...Part No 1268494 S 100 S 105 S 120 S 125 6 43 March 2017 Section 6 Schematics Perkins 854F 34T Engine Electrical Harness ...

Страница 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Страница 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Страница 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Страница 272: ...6 48 S 100 S 105 S 120 S 125 Part No 1268494 March 2017 Section 6 Schematics Deutz TD2 9 Engine Electrical Schematic ...

Страница 273: ...Part No 1268494 S 100 S 105 S 120 S 125 6 49 March 2017 Section 6 Schematics Deutz TD2 9 Engine Electrical Harness ...

Страница 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Страница 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...

Страница 277: ...Section 6 Schematics March 2017 6 53 Hydraulic Schematic S 100 S 105 Models serial number 136 6 54 ...

Страница 284: ...March 2017 Section 6 Schematics 6 60 Hydraulic Schematic S 100 S 105 Models from serial number 739 6 61 ...

Страница 293: ...Section 6 Schematics March 2017 6 69 Hydraulic Schematic S 120 S 125 Models from serial number 3146 to S12514D 921 6 70 ...

Страница 296: ...March 2017 Section 6 Schematics 6 72 Hydraulic Schematic S 120 S 125 Models from serial number S12514D 922 6 73 ...