M-40 OPERATOR & SERVICE MANUAL

ISSUE 05/01

OPERATION

SECTION B – PAGE 32

B.7c

Compressor Preventive Maintenance

CAUTION: Always use SJ-27 oil as other types of oil may cause serious

mechanical damage to the compressor. Consequently the warranty

only applies if SJ-27 oil is used.

Pumping times 0-8 bar (0 - 120 psi),

230V/50Hz, = 110 seconds

The pumping time indicates the condition of the compressor provided that

there are no leaks in the system where the compressed air may leak. Test

the compressor as follows:

1)

Empty the air receiver of compressed air (The pressure gauge shows 0

bar).

2)

Close the outlet on the air receiver and check that the drain cock is

closed.

3)

Start the compressor and note how long it takes until it switches off.

Make sure that the pressure in the air receiver is 8-bar/120 psi as deviations

may indicate the wrong results.

CAUTION: Always test the compressor when cold as the time indicated

refers to the pumping time of a cold compressor. The pumping time

of a warm compressor is much longer and consequently, the result

would be misleading.

Check the compressor oil

level whenever the cabinet is

open.

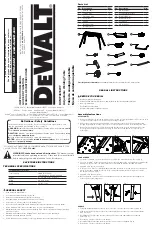

Adding Lubricant to Compressor:

Remove filler cap.

Insert unstopped end of tubing into filler hole.

Carefully tilt bottle to pour controlled amount of lubricant into filler hole.

Oil levels should be between MIN. and MAX. levels indicated at window.

Adding Lubricant to Compressor

Intake filter element

Auto drain bottle

Safety Air Relief

Valve Test

Содержание M-40

Страница 6: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 COVER 071 27939 400 6 NOTES...

Страница 43: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 OPERATION SECTION B PAGE 27 Purge Screen Glue System Diagram...

Страница 50: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 OPERATION SECTION B PAGE 34 NOTES...

Страница 52: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 ALARM MESSAGES SECTION E PAGE 2 NOTES...

Страница 63: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 REPAIR AND REPLACEMENT SECTION F PAGE 11 NOTES...

Страница 79: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 16 002B 18043 AUXILIARY FEED BELTS 1 2 3 4 5 6 7...

Страница 83: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 20 002B 16631 FRONT SHAFT ASSEMBLY 7 1 2 3 4 5 6...

Страница 91: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 28 703 27277 500 FOLDER 4 PLATE PAGE 1...

Страница 93: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 30 703 27277 500 FOLDER 4 PLATE PAGE 2...

Страница 95: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 32 703 27277 500 FOLDER 4 PLATE PAGE 3...

Страница 97: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 34 703 27277 500 FOLDER 4 PLATE PAGE 4...

Страница 114: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 51 NOTES...

Страница 117: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 54 750 27251 000 EXIT CONVEYOR PAGE 2...

Страница 119: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 PARTS SECTION G PAGE 56 NOTES...

Страница 138: ...M 4 OPERATOR SERVICE MANUAL ISSUE 05 01 MAINTENANCE SECTION C PAGE 5...

Страница 147: ...M 40 OPERATOR SERVICE MANUAL ISSUE 05 01 MAINTENANCE SECTION C PAGE 14 NOTES...