7

V19

V18

DPS

S

V20

LEFT TOWER

RIGHT TOWER

F4

F3

O3

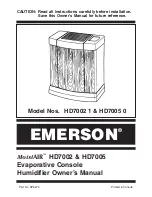

Figure 4.3

Legend

Item

Description

V18 & V19

Left & Right air sample isolation valves

F3 & F4

Left & Right air sample filters

V20

Air sample switching vlave

DPS

Dew point sensor

O3

Air sample flow orifice

B. Fixed Cycle - Two Stage Regeneration (Optional)

(1) Left Tower Drying - Right Tower Regenerating

At the start of the drying cycle, both inlet valves

(V1,V2) are open. The right inlet valve (V2) is then

closed to isolate the two towers. Wet, compressed

air flows up through the left tower where it is dried.

The dry air exits the dryer through the outlet check

valve (V7).

Next, the right depressurization valve (V6) is opened

and the right tower is slowly depressurized. Air exits

through an exhaust muffler (M2).

In preparation for the first stage regeneration, the

right purge valve (V4) is opened. Next, the blower

(B1) and heater (H1) are energized. The heated air

flows through check valve (V10), down through the

right tower, and exits through the right purge valve

(V4). The blower intake air is filtered (F1) to keep dust

and dirt from entering the dryer. The blower (B1) and

heater (H1) are de-energized when the temperature

at the bottom of the right tower, as sensed by

temperature switch (TS2), reaches the design set

point. This indicates the bed has been fully heated.

To fully seat check valve (V10) and prevent back flow

through the heater (H1) and blower (B1) during the

second stage regeneration, the right tower is partially

pressurized and then depressurized as follows. First,

the right purge valve (V4) is closed and the

repressurization valve (V15) is opened. The pressure

in the right tower begins to rise and check valve (V10)

is seated. Next, the repressurization valve (V15) is

closed and the depressurization valve (V6) is opened,

depressurizing the tower. Finally, the right purge

valve (V4) and repressurization valve (V15) are opened,

starting the second stage regeneration.

A portion of the dry air from the left tower now flows

through repressurization valve (V15). This air is

throttled to near atmospheric pressure by two

orifices (O1,O2). The dry, low pressure air flows down

through the right tower and exits through the purge

valve (V4).

At the end of the second stage regeneration, the

right purge valve (V4) is closed and the tower slowly

repressurizes to full line pressure. The right tower is

now ready to go back on-line.

(2) Right Tower Drying - Left Tower Regenerating

At the start of the drying cycle, both inlet valves

(V1,V2) are open. The left inlet valve (V1) is then

closed to isolate the two towers. The right tower is

now on-line, drying the compressed air. The left

tower will be regenerated, following a similar se-

quence as described in Section 4.3.B.(1) for the right

tower.

C. Demand Cycle (Optional)

Operation of the demand cycle is identical to the

fixed cycle (see Sections 4.3.A and B) except the cycle

is extended until the desiccant bed in the on-line

tower has been fully utilized. The off-line tower is

regenerated and remains in a stand-by mode after

being repressurized.

Figure 4.3 shows the air sampling system for the

demand cycle option. When the left tower is drying

and the right tower is regenerating, an air sample

from the left tower flows through an isolation valve

(V18), a filter (F3), and the sampling valve (V20) to the

dew point sensor (DPS). The sample flow rate is

controlled by a fixed orifice (03). The sample exhausts

to atmosphere.