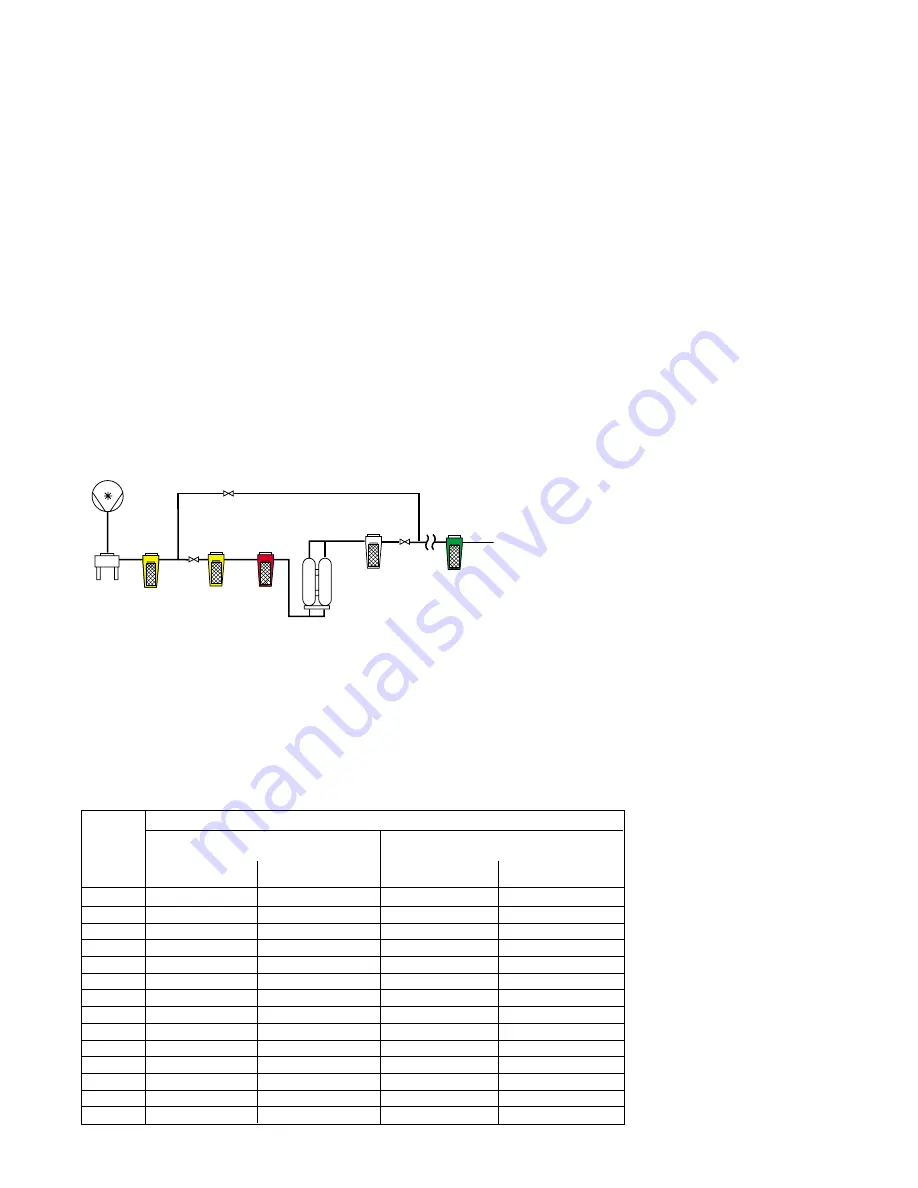

3

Minimum pipe size (IPS)*

Dryers with One Stage Regeneration

Dryers with Two Stage Regeneration

(Standard)

(Optional)

Up to 50 feet of

Up to 100 feet of

Up to 50 feet of

Up to 100 feet of

pipe plus 4 fittings

pipe plus 4 fittings

pipe plus 4 fittings

pipe plus 4 fittings

525

3

4

4

4

775

4

4

4

6

1050

4

6

6

6

1300

6

6

6

6

1575

6

6

6

6

1825

6

6

6

8

2100

6

6

6

8

2625

6

8

8

8

3150

8

8

8

8

3675

8

8

8

10

4200

8

8

10

10

4725

8

10

10

10

5250

10

10

10

10

5800

10

10

10

10

*Exhaust piping configuration - For Models and configurations other than those listed above, contact the factory for assistance.

Dryer

Model

Number

* Use if high liquid loads are present and to protect the oil removal

filter from gross contamination

** Install downstream where air has cooled to at least 150

°

F (66

°

C).

Figure 3.2 - Pipe Sizing Chart for Purge Exhaust Lines

By-Pass Valves

Compressor

Aftercooler

Blower Purge

Dryer

Separator

High

Efficiency

Oil Removal

Filter

Prefilter

(Optional)*

Oil Vapor

Removal Filter

(Optional)**

High Temperature

Afterfilter

Figure 3.1

3.0 Installation

3.1 Location in Compressed Air System

The dryer should be located downstream of an

aftercooler and separator for best performance.

Prefilters are necessary to protect the desiccant beds

from liquid and solid contamination. Locate the

prefilters as close to the dryer inlet as possible. Use

an Air Line Filter in systems supplied by a non-

lubricated (oil free) air compressor. In systems

supplied by a lubricated air compressor, use a High

Efficiency Oil Removal Filter. A coarser filter will be

required upstream of the Oil Removal Filters if heavy

liquid or solid loads are present.

An afterfilter should be used to protect downstream

equipment from desiccant dust. A High Temperature

Afterfilter, typically rated at a 450

°

F (232

°

C) operating

temperature and capable of removing all desiccant

fines 1 micron and larger should be provided.

The use of bypass valves and piping allows servicing

of the filters and/or dryer without interrupting the air

flow.

3.2 Ambient Temperature Limitations

The dryer should not be installed in an area where the

ambient temperature will exceed 120

°

F (49

°

C) or fall

below 40

°

F (4.4

°

C) unless the unit has been equipped

for operation in higher and/or lower ambient condi-

tions.

3.3 Mounting

Locate the dryer on a solid level floor. Ensure the

dryer is level by grouting or shimming as necessary.

Securely anchor the dryer frame to the floor. Provide

a four (4) foot (1.2 m) wide access area on all sides of

the dryer and overhead clearance of four (4) feet (1.2

m) for ease of servicing and visibility of instrumenta-

tion.

3.4 Air Inlet and Outlet Connections

Connect compressed air lines to the dryer inlet and

outlet using pipe of diameter equal to or larger than

the pipe size on the dryer. Be sure to use a flange

gasket suitable for high temperature on the air outlet

flange. The gasket must be able to withstand the

temperature spike that occurs at tower switchover

typically 300-325

°

F (149-163

°

C).

3.5 Electrical Hook-up

WARNING:

These procedures require gaining access

to the dryer’s electrical enclosure(s). All electrical

work must be performed by a qualified electrical

technician.

Connect the proper power supply to the dryer

according to the electrical drawings. Be sure to

follow all applicable electrical codes. After power is

connected to the dryer, manually engage the blower

motor starter to ensure proper blower rotation.

Dry contacts (voltage free) are provided in the main

electrical enclosure for a remote alarm. The contact

ratings are shown on the electrical drawing.

3.6 Purge Exhaust Piping

In some installations, it may be necessary to pipe the

purge exhaust outdoors since condensation may

become a problem. The purge exhaust piping must

be sized according to the chart shown in Figure 3.2.