RM7895A RELAY MODULE

19

32-00122-01

3.

Close all manual main fuel shutoff valves. Check

that the automatic fuel valves are closed. Make sure

fuel is not entering the combustion chamber.

4.

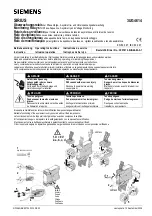

Close the master switch and start the system with a

call for heat by raising the set point of the operating

controller, see Fig. 11. The primary sequence should

start the ten-second INITIATE sequence.

5.

Let the sequence advance through PREPURGE.

Ignition spark should occur after the PREPURGE

period. Listen for the click of the first stage fuel

solenoid valve(s).

6.

Let the program sequence complete its cycle.

7.

Open the manual fuel shutoff valve(s).

8.

Reset the Lockout Switch and recycle the primary

sequence through PREPURGE.

9.

Watch for the FLAME LED to help determine when

the first stage burner flame is established. If it is

established, proceed to step 15.

10.

If the first stage burner flame is not established

within four seconds, or within the normal lightoff

time specified by the equipment manufacturer, close

the manual fuel shutoff valve(s) and open the

master switch.

11.

Check all burner adjustments.

12.

Wait about three minutes. Close the master switch,

open the manual fuel shutoff valve(s), and try again

to lightoff the burner. The first attempt may have

been required to purge the lines and bring sufficient

fuel to the burner.

13.

If the first stage burner flame is not established

within four seconds, or within the normal lightoff

time specified by the equipment manufacturer, close

the manual fuel shutoff valve(s) and open the

master switch.

14.

If necessary, repeat steps 8 through 13 to establish

the first stage burner flame. Then proceed to step

15.

15.

When the first stage burner flame is established, the

sequence will advance to RUN. Make burner

adjustments for flame stability and input rating. If a

second stage is used, proceed to step 18.

16.

Shut down the system by opening the burner switch

or by lowering the set point of the operating

controller. Make sure the burner flame goes out and

make sure all automatic fuel valves close.

17.

If used, remove the bypass jumpers from the low fuel

pressure limit and subbase.

18.

If a second stage is used, make sure the automatic

second stage fuel valve(s) has opened and check the

lightoff as follows. Otherwise, proceed to step 19.

a. Open the manual second stage fuel valve(s).

b. Restart the system by raising the set point of the

operating controller.

c. When the first stage burner flame is established,

watch for the automatic second stage fuel

valve(s) to open. Observe that the second stage

lights off properly.

d. Make burner adjustments for flame stability and

input rating.

e. Shut down the system by lowering the set point

of the operating controller. Make sure the burner

flame goes out and all automatic fuel valves

close. Proceed to step 19.

19.

Restart the system by closing the burner switch

and/or raising the set point of the operating control-

ler. Observe that the burner flame is established

during PILOT IGN, within the normal lightoff time

specified by the equipment manufacturer.

20.

Measure the flame signal. Continue to check for the

proper signal, see Table 8, through the RUN period.

Any pulsating or unsteady readings will require

further attention.

21.

Make sure all readings are in the required ranges

before proceeding.

NOTE:

Upon completing these tests, open the master

switch and remove all test jumpers from the sub-

base terminals, limits/control or switches.

22.

Return the system to normal operation.

Pilot Turndown Test (All

Installations Using a Pilot)

Perform this check on all installations that use a pilot. The

purpose of this test is to verify that the main burner can be

lit by the smallest pilot flame that will hold in the flame

amplifier and energize the FLAME LED. Clean the flame

detector(s) to make sure it will detect the smallest

acceptable pilot flame.

NOTE:

Low fuel pressure limits, if used, could be open. If

so, bypass them with jumpers during this test.

1.

Open the master switch.

2.

Close the manual main fuel shutoff valve(s).

3.

Connect a manometer (or pressure gauge) to mea-

sure the pilot gas pressure during the turndown test.

4.

Open the manual pilot shutoff valve(s).

5.

Close the master switch and start the system with a

call for heat. Raise the set point of the operating

controller. The primary sequence should start and

PREPURGE should begin.

NOTE:

INTERMITTENT PILOT MODELS should continue

with step 6.

6.

INTERMITTENT PILOT MODELS—After the

sequence has entered the normal burner run period,

turn the pilot gas pressure down very slowly, reading

the manometer (or gauge) as the pressure drops.

Stop immediately when the FLAME LED goes out.

Note the pressure at this point.

a. If the Flame Failure Action jumper is not clipped:

allow the RM7895A to recycle through PRE-

PURGE. If the Flame Failure Action jumper is

clipped: push the reset push button and allow

the RM7895A to recycle through PREPURGE.

b. As the control attempts to relight the pilot, turn

the pilot gas pressure back up slowly until the

FLAME LED comes on. This step must be com-

pleted within 4 or 10 seconds, depending on the

selected PFEP, or lockout will occur.

c. Turn the pilot back down slightly but not enough

to cause the FLAME LED to go out. (Keep the gas

pressure just above the reading noted in step 6

above.)

NOTE:

Step d requires two people, one to open the man-

ual main fuel valve(s) and one to watch for igni-

tion.