66

106346-06 - 8/19

FORCE

Installation, Operating & Service Manual

When

A low water cutoff is required to protect a hot

water boiler when any connected heat distributor

(radiation) is installed below the top of the hot

water boiler (i.e. baseboard on the same floor

level as the boiler). In addition, some jurisdictions

require the use of a LWCO with a hot water boiler.

Where

The universal location for a LWCO on both gas

and oil hot water boilers is above the boiler, in

either the supply or return piping. The minimum

safe water level of a water boiler is at the

uppermost top of the boiler; that is, it must be full

of water to operate safely.

It is recommended that the LWCO control

is installed above the boiler to provide the

highest level of protection. However, where

the LWCO control is approved by the LWCO

control manufacturer for installation in a high

boiler tapping of a water boiler, the use of the

listed LWCO control is permitted when it is

installed according to the LWCO manufacturer’s

instructions.

What Kind

Typically, in residential applications, a probe type

LWCO is used instead of a float type, due to their

relative costs and the simplicity of piping for a

probe LWCO.

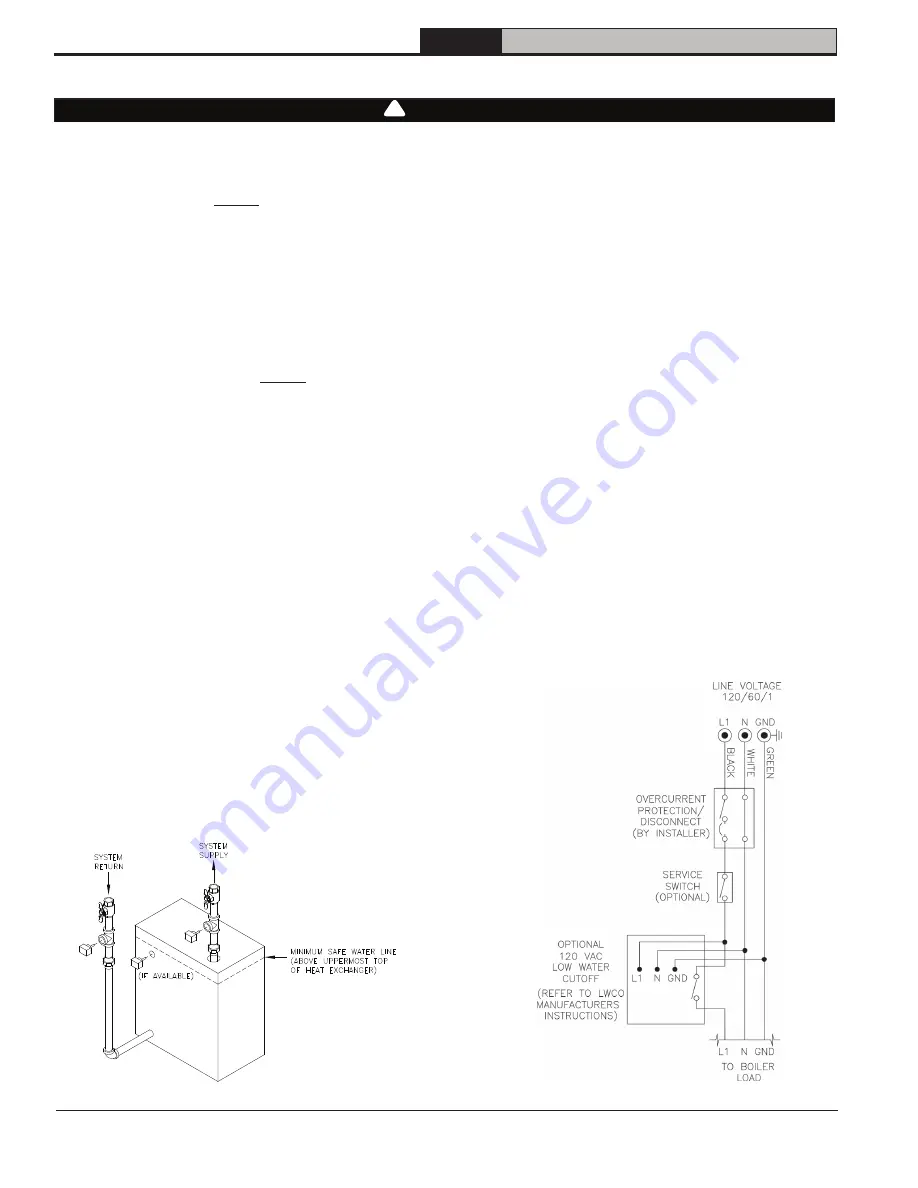

How to Pipe

A “tee” is commonly used to connect the probe

LWCO to the supply or return piping, as shown

below.

LWCO Location

Wiring of Typical LWCO

Appendix A:

Aftermarket Low Water Cut Off (LWCO) On Hot Water Boilers

WARNING

•

DO NOT ATTEMPT to cut factory wires to install an aftermarket Low Water Cut Off (LWCO).

Only use connections specifically identified for Low Water Cut Off.

• In all cases, follow the Low Water Cut Off (LWCO) manufacturer's instructions.

!

Select the appropriate size tee using the LWCO

manufacturer’s instructions. Often, the branch

connection must have a

minimum

diameter

to prevent bridging between the probe and the

tee. Also, the run of the tee must have a minimum

diameter to prevent the end of the probe from

touching or being located too close to the inside

wall of the run of the tee.

Ideally, manual shutoff valves should be located

above the LWCO and the boiler to allow for

servicing. This will allow probe removal for

inspection without draining the heating system.

Many probe LWCO manufacturers recommend an

annual inspection of the probe.

How to Wire

LWCO’s are available in either 120 VAC or 24 VAC

configurations. The 120 VAC configuration can

be universally applied to both gas and oil boilers

by wiring it in the line voltage service to the boiler

(after the service switch, if so equipped).

The presence of water in a properly installed

LWCO will cause the normally open contact of the

LWCO to close, thus providing continuity of the

120 VAC service to the boiler.

It is recommended to supply power to the probe

LWCO with the same line voltage boiler service as

shown below.

Содержание FORCEOL115-E

Страница 56: ...56 106346 06 8 19 FORCE Installation Operating Service Manual Bare Boiler Assembly 15 Service Parts continued...

Страница 58: ...58 106346 06 8 19 FORCE Installation Operating Service Manual Jacket Assembly 15 Service Parts continued...

Страница 61: ...61 106346 06 8 19 FORCE Installation Operating Service Manual Beckett AFG Burner 15 Service Parts continued...

Страница 63: ...63 106346 06 8 19 FORCE Installation Operating Service Manual Beckett NX Burner 15 Service Parts continued...