Flint & Walling © Copyright 2018. All rights reserved.

6

"S2" on the display board terminal strip with a small

screwdriver (provided) .

Tighten the strain relief on the pressure switch/transducer

lead .

IL0026

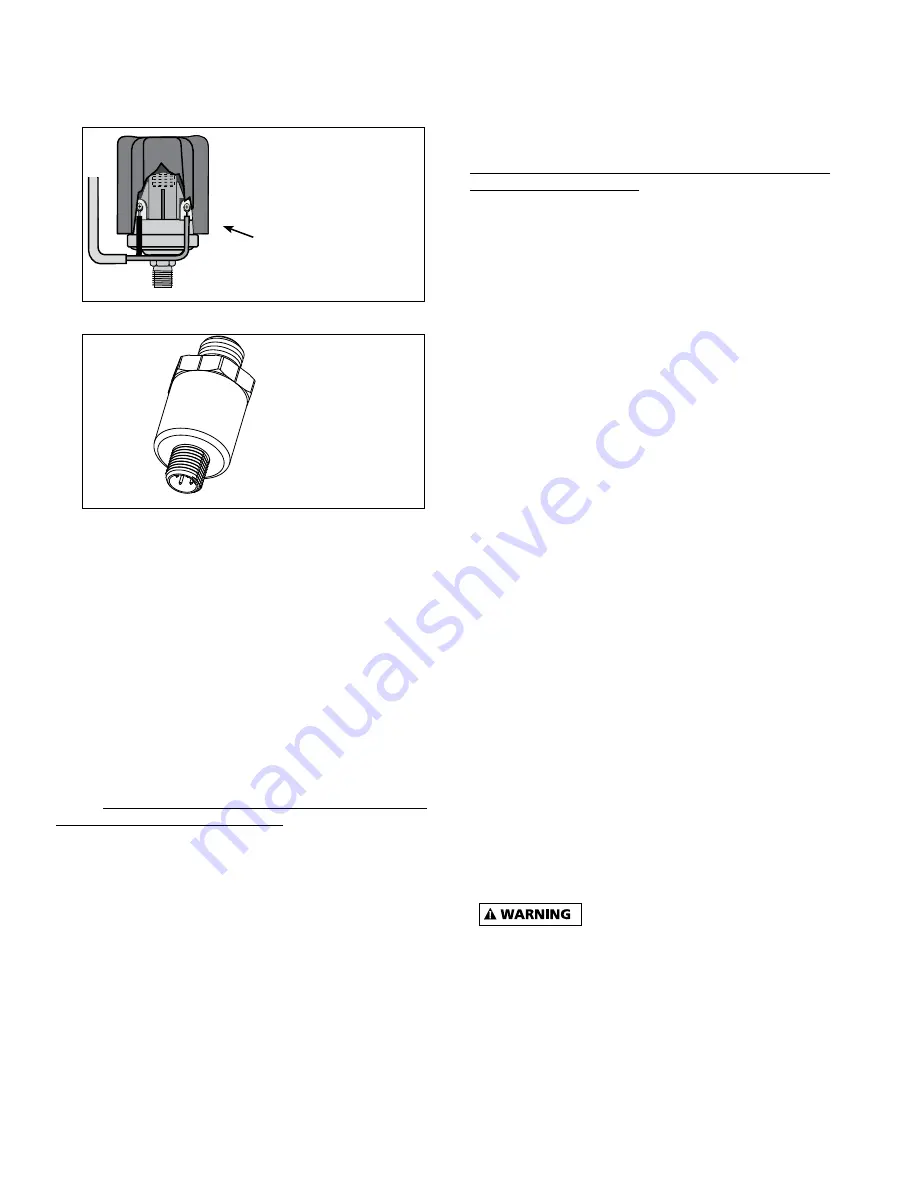

Remove rubber end cap

to adjust pressure . Use

7/32” allen wrench

Pressure switch

boot

Figure 7 Pressure Switch

IL1875

Figure 8 Pressure Transducer

A 10 foot section of cable is provided with the system

to connect to the pressure switch / transducer. Lengths

of up to 100 feet can be used, provided the appropriate

shielded cabling is used. Consult the factory for proper

cable specification.

7 . Use the appropriate strain relief or conduit connectors

(not included) .

8 . Replace the cover . Do not over-tighten the screws .

9 . Set the pressure tank pre-charge to 70% of the desired

water pressure setting . To check the tank’s pre-charge,

de-pressurize the water system by opening a tap .

Measure the tank pre-charge with a pressure gauge at its

inflation valve and make the necessary adjustments .

NOTE

: For pressure switch installation (VS systems) only,

Follow steps 10, 11 & 12 . (Figure 7)

For pressure transducer installations, skip to Step 13 .

10 . Connect the other end of the pressure switch cable with

the two spade terminals to the pressure switch . The

connections are interchangeable .

11 . The pressure switch communicates the system pressure

to the controller . The switch is preset at the factory to

50 psi, but can be adjusted by the installer using the

following procedure:

a . Remove the rubber end-cap .

b . Using a 7/32” Allen wrench (provided), turn the

adjusting screw clockwise to increase pressure

and counter-clockwise to decrease pressure . The

adjustment range is between 30 and 80 psi (1/4 turn =

approximately 3 psi) .

c . Replace the rubber end cap .

d . Reset the pressure tank pre-charge to the appropriate

pressure

12 . Cover the pressure switch terminals with the rubber boot

provided .

For pressure transducer installation (TVS systems) only,

Follow Step 13 . (Figure 8):

13 . Connect the free end of the transducer cable to the

transducer by lining up the keyway on the connector

to the transducer, pressing the cable into place & then

tightening the thumbscrew finger tight .

START-UP OPERATION

Apply power to the controller . The display should briefly show

“Please Wait Initializing” and then read “Press Enter to Begin

Set-Up” . Pressing ENTER button will begin taking you through

the quick set-up menu where you can select Pump type

(Submersible or Above Ground); Motor type (Three Phase,

3W Single Phase - if option is available); Maximum Motor

Current; Maximum Frequency; Control (Switch, Transducer)

by using the UP & DOWN buttons to change the setting

and then pressing the ENTER button to save the choice .

Once all the choices have been selected, press the STOP/

START button to save the setting to the controller’s memory .

The drive will then spin the motor in a reverse direction for

a couple of seconds and then begin to run the motor in the

correct direction and begin regulating the pressure . While the

drive is running the motor, for VS drive kits (pressure switch)

the display will show the current that the motor is drawing and

the frequency that is being supplied . When there is no water

use, the controller will shut off the output to the motor and the

display will show “Motor is in Standby Mode” . For TVS drive

kits (transducer) the display will show the transducer pressure

reading, current that the motor is drawing and the frequency

that is being supplied .

NOTE

: Conventional private water systems intermittently fill a

pressure tank as commanded by a standard pressure switch

(e .g . 30 - 50 psi) . The constant pressure controller maintains

a constant pressure at the pressure switch/transducer up to

the maximum capability of the motor and pump . Although the

pressure is constant at the pressure switch or transducer,

pressure drops may be noticeable in other areas of the home

when additional taps are opened . This is due to limitations in

the plumbing and will be more pronounced the further the taps

are from the pressure switch/transducer . This would be true of

any system, and if observed, should not be interpreted as a

failure in the performance of the constant pressure controller .

Serious or fatal electrical shock may

result from contact with internal electrical components.

DO NOT, under any circumstances, attempt to modify

connections to the drive until power has been removed

and 10 minutes have passed for internal voltages to

discharge!