Flint & Walling © Copyright 2018. All rights reserved.

7

Underload Sensitivity

The controller is configured at the factory to ensure detection

of Underload faults in a wide variety of pumping applications

including dead head and run dry conditions . In very rare

cases (as with certain pumps in shallow wells) this trip level

may result in nuisance faults . If the pump is installed in a

shallow well, activate the controller and observe system

behavior . Once the controller begins to regulate pressure,

check operation at several flow rates to make sure the default

sensitivity does not induce nuisance Underload trips . If it

becomes necessary to desensitize the Underload trip level,

please call of Technical Support at 800-742-5044 for further

details .

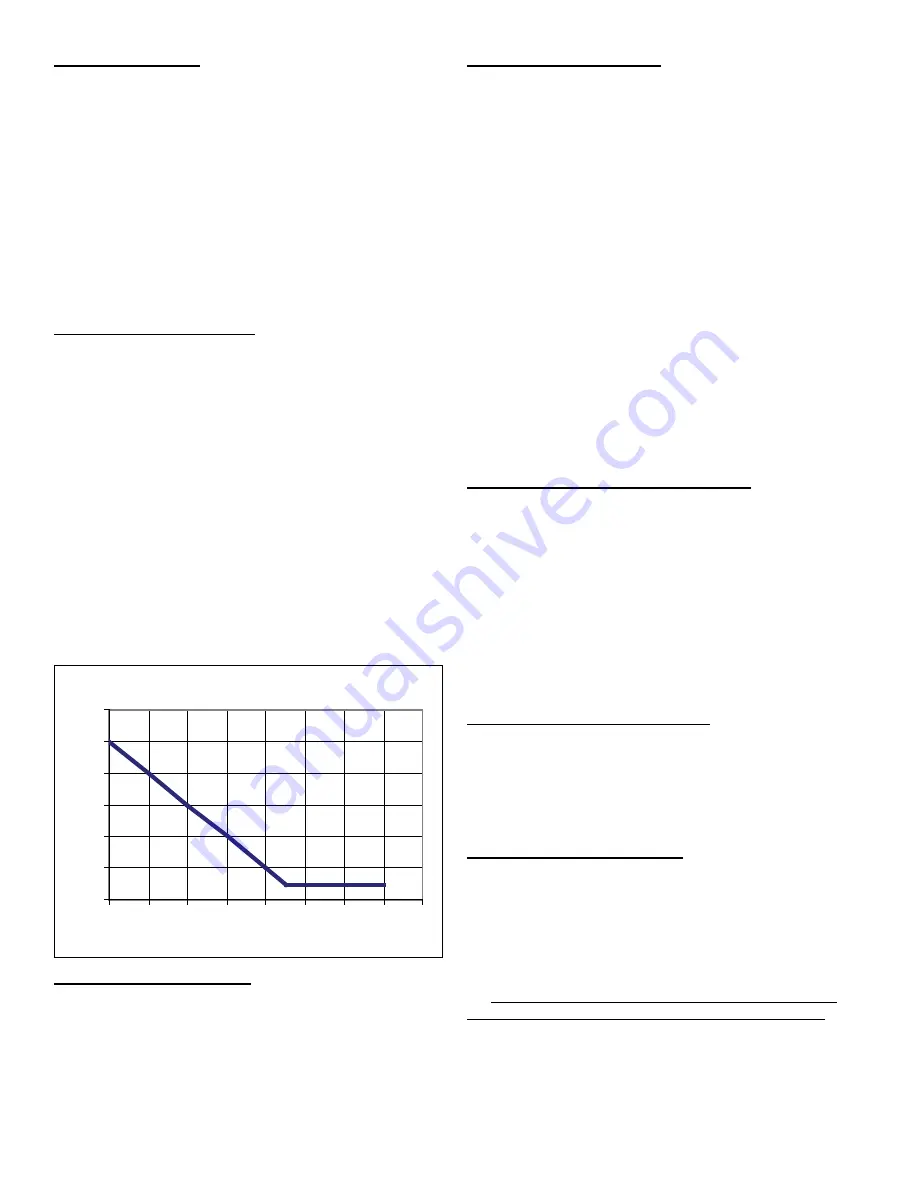

UNDERLOAD INTELLIGENT RESET

(Display shows Dry Well Trip)

If a motor Underload fault condition occurs, the most likely

cause is an over-pumped well (dry well) or loss of incoming

feed water to the pump . In a dry well situation to allow

the well to recover, the controller will wait 30 seconds to 5

minutes, determined by the amount of time the motor had

been running before sensing the dry well, before restarting

the motor . For example, the first time the fault occurs and

the pump has been running 6 minutes, the controller stop the

motor and will wait 30 seconds before attempting to restart

the pump . If the system would then run for 2 minutes and an

dry well fault recurs, the controller will wait 3 minutes before

attempting to restart the pump . This schedule allows for the

minimum off-time possible based on the recovery time of the

well .

If there is an obstruction (such as a closed valve) between

the pump and the pressure switch/transducer, the controller

will also sense an underload deadhead condition stopping the

motor to avoid damaging the pump .

0

1

2

3

4

5

6

0

1

2

3

4

5

6

7

8

IL1448

Run Time (Minutes)

O

ff

T

im

e

(M

in

ut

es

)

“Intelligent Reset” Recovery Time

Over Temperature Protection

The controller is designed for full power operation in ambient

temperatures to up to 125°F (50°C) as long as the input

voltage is at 230V . Under severe thermal situations, the

controller will reduce power output by reducing the output

frequency in order to avoid shutting down . Full speed output

is restored when the temperature cools .

External alarm trip terminals

The control is fitted with an Alarm In terminal block on the

display board . Using these terminals, an external control

switch can be wired to the drive . With this connection, an

external control such as an over pressure, under pressure,

timer, low level switch, etc . can be used to trip the drive with

an “External Fault” trip . For this connection to work properly,

the Alarm in Relay contact condition setting in the Advanced

Features Menu must be set to match the switch position

to activate the drive . (Example: An irrigation timer closes a

contact to single the drive to run, the Alarm In Relay setting

should be set to NC (Normal Closed) for the drive to be active

during the irrigation cycle .)

This connection can also be used with the “External Control”

feature in the advanced options menu to put the drive in

standby rather than causing an external fault trip .

Caution: The external control must be a dry contact

(i.e. no voltage applied to the Alarm In terminals of the

controller) to not damage the drive circuit boards. An

external control with voltage can only be used with the

controller if an isolation relay is used in conjunction with

the voltage source. Contact technical support for more

information.

Leaky Systems (Pressure Switch Control)

Leaky water systems might keep the controller running due

to the accurate pressure sensing capability of the pressure

switch . Continuous running or starts and stops do not hurt

the controller, pump or motor . However, to reduce the on-time

of the controller/pump/motor, a “Bump-Mode” has been

programmed into the drive . During very low flow (or leaky)

conditions this feature periodically increases the speed of the

pump several PSI above the set point and shuts off the pump .

This adds some time to bleed off before the system starts

up again . This “Bump-Mode” can be turned off or adjusted if

desired . Please call Technical Support at 800-742-5044 for

further details .

Fill Pipe Mode (Transducer Control)

At initial power up, the drive is automatically in the Fill Pipe

Mode for 3 minutes . This allows a new installed system to

fill the pip and build up pressure without having the pump

trip out because it is sensing low pressure . If additional time

is needed, this mode can be turned back on and the time

increased in Parameter menu #7 .

Use of Engine Drive Generators

There are several technical issues that go into correct sizing

of a generator for use with a VFD controller . Since the VFD

is a “non-linear load”, the generator needs to be oversized

considerably for proper operation . Listed below is minimum

recommended sizing of a generator for each drive rating if the

VFD controller is the only load on the generator . Because of

the variation in design of voltage controls used in generators,

the generator manufacture should always be contacted to

verify the correct sizing when used with a VFD controller .

For best results when used with a generator in the Advanced

Features Menu the

Powered by Generator option needs to

be set to “Yes”.