Page 2

OPERATION

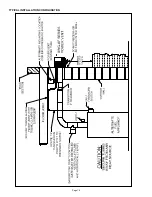

The SWG-AF series power vents are designed for sidewall venting of a single listed automatic feed Corn,

Wood Pellet and other Bio-fuel burning heating appliances.

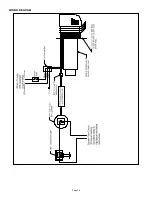

1. The power vent operates continuously while the heating appliance is in operation. After the mechanical

draft vent motor has come up to speed, the pressure switch closes. This closes the circuit to the burner

feed circuit and allows the burner to fire.

2. A barometric draft control is required to maintain the proper draft through the appliance. It also

regulates the appliance venting under extreme changes in windy weather conditions.

3. A pressure sensing switch and blocked vent safety switch are wired into the burner feed circuit. If

proper venting is not maintained, one or both switches will open and the burner feed circuit will de-

activate.

TO THE USER

For continued safe operation, the heating appliance MUST be cleaned and inspected annually by a qualified

service agency. It is recommended that the owner operator should have the appliance and power vent system

examined annually for deterioration from corrosion or other sources. The inspection should be performed prior

to each heating season.

ELECTRICAL DATA

Power Vent Operating Current:

SWG-4AF/5AF: 1.77A @ 115V and SWG-6AF: 1.3A @ 115V

Maximum Pressure Switch Current:

10A @ 120V

Maximum Blocked Vent Switch Current:

10A @ 120V

INSTALLATION SAFETY INSTRUCTIONS

WARNING: The SWG-AF power vent system must be installed by a qualified agency.

The definition of a qualified agency is: “.. any individual, firm, corporation, or company who either in person or through a

representative is engaged in, and is responsible for installation and operation of solid or bio-fuel heating appliances. Who

is experienced in such work, familiar with all the precautions required, and has complied with the requirements of the

authority having jurisdiction”.

The installer must write or imprint his name, phone number and date of installation on the installation tag.

The tag should be attached to the power venting unit.

Recording burner and venting system initial operational information is strongly recommended as a guide for

service or burner tune-up. Enter recorded information on the back page of this manual.

1. Safety inspection of a venting system must be performed before and after installing a power venting system on an

existing or new appliance. Procedures to follow are those recommended latest version of:

In the USA

NFPA 211 Standard for Fireplaces, Vents and Solid Fuel-Burning Appliances, The International Mechanical

Code and / or International Residential Code or refer to the General Installation Inspection section of this

manual.

In Canada

CSA B 365 Installation Code for Solid Fuel-Burning Appliances and Equipment

2. Plan the vent system layout before installation to avoid the possibility of accidental contact with concealed wiring,

plumbing inside walls and combustible materials.

CAUTION

The Field Controls DIP-1 pressure switch, Barometric Draft Control and WMO-1 blocked vent switch must

be properly installed and interlocked to the appliance burner feed circuit. See the appliance manufacturer’s installation

instructions for proper wiring. The power vent and draft equipment is only for use as a venting option for specific listed

automatic fuel-burning appliances; refer to the appliance manufacturer’s instructions for proper application and installation.

Содержание SWG-AF Series

Страница 10: ...Page 10 WIRING DIAGRAM...

Страница 15: ...Page 15 TYPICAL INSTALLATION CONFIGURATION...

Страница 17: ...Page 17...

Страница 35: ...Page 17...