Page 11

Figure 15

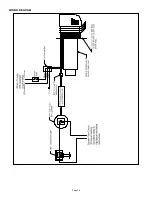

Figure 16

MAINTENANCE

1.

Motor:

Inspect the motor once a year - motor should rotate freely. To prolong the life of the motor, it must be

lubricated with six drops of SWG Superlube, Part # 46226200, annually.

2.

Wheel:

Inspect the power vent wheel annually to clear any soot, ash or coating which inhibits either rotation or air

flow. Remove all foreign materials before operating.

3.

Vent System:

Inspect all vent connections annually for looseness, for evidence of corrosion, build up of soot and

for flue gas leakage. Replace, seal or tighten pipe connections if necessary. Check the power vent choke plate to

insure it is secured in place. Check the barometric draft control, if installed, to insure the gate swings freely.

4.

System Safety Devices:

With the heating system operating, disconnect the pressure sensing tube from the

pressure switch. This will stop the burner feed operation. Re-connecting the tube will restart the burner feed

system.

REPLACEMENT PARTS

Should the motor blower wheel assembly need replacement, the following items are available. The SWG-AF Repair Motor

Kit contains the Motor and Blower Wheel. It is factory assembled to a mounting bracket.

MODEL

REPAIR MOTOR KIT

SWG-4AF 46544400

SWG-5AF 46544500

SWG-6AF 46544600

REMOVAL AND INSTALLATION OF THE SWG-AF SERIES POWER VENT MOTOR ASSEMBLY

R

EMOVAL

1. Remove the motor enclosure cover by loosening the four screws.

2. Open the electrical box on the motor and disconnect the conduit and wires from the

motor. (See Figure 15)

3. Remove the four nuts securing the motor assembly, and pull the motor assembly

straight off of the unit. (See Figure 16)

4. Clean off any build-up inside the blower wheel housing and blower wheel.

I

NSTALLATION

1. Align holes in the circular cover plate with holes in the motor mount bracket on

the motor assembly. (See Figure 15)

2. Slide motor assembly onto protruding threaded studs on the power vent body.

The exhaust chute must be pointing downward. Replace the four nuts securely to

the threaded studs. (See Figure 16)

3. Re-attach flexible conduit and wires to motor and secure cover on the electrical

box.

4. Install motor cover with the side louvers pointing downward.

CAUTION

Avoid applying excess pressure on the blower wheel when

cleaning off any build-up of material. This will cause an imbalance of the blower

wheel which results in excessive vibration and premature motor failure.

Содержание SWG-AF Series

Страница 10: ...Page 10 WIRING DIAGRAM...

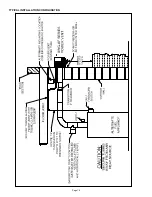

Страница 15: ...Page 15 TYPICAL INSTALLATION CONFIGURATION...

Страница 17: ...Page 17...

Страница 35: ...Page 17...