48

Festo — VTSA-F-CB — 2021-06a

Product overview

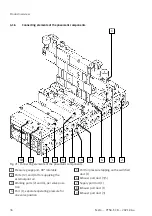

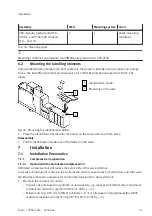

Explanations for example 3:

L

Duct separation 14

USW

Additional supply plate/exhaust plate with address extension for safe voltage zone

K

Duct separation 1/3/5/14 (note on necessary additional pilot air supply)

XC

Adapter plate with CPX pneumatic interface, for expansion by 3 safe internal zones (PROFI-

safe)

Z

External pilot air supply right-hand end plate

AB / CB Blanking plug

Tab. 30: Explanations for example 3

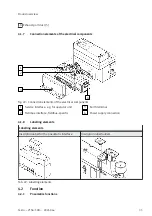

4.3

Operating modes

Depending on the types of valve used, the following valve terminal operating modes can be used:

–

Standard operation with one or more pressure zones

–

Reversible operation with compressed air supply via ports (3) and (5) and exhaust via port (1)

–

Low-pressure operation at 0 … 3 bar

–

Vacuum operation at –0.9 … 0 bar

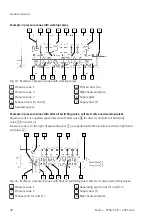

4.3.1

Vacuum operation or low-pressure operation

The following valves with supply via port (1) are not suitable for vacuum or low pressure:

• Soft start valves

• Pilot air switching valves with internal pilot air supply

• 2x 3/2-way valves (ID codes H, QH, K, QK, N and QN)

The following requirements must be met to enable the valve terminal at the supply port (1) to operate

with vacuum or low pressure between –0.9 … 3.0 bar:

–

The pilot control is operated with an external pilot air supply.

–

Pressure zones with vacuum operation or low-pressure operation are equipped exclusively with the

following valves:

–

5/2-way valves, monostable (ID codes M, QM, O and QO)

–

5/2-way valves, bistable (ID codes D, QD, J and QJ)

–

5/3-way mid-position valves (ID codes B, QB, E, QE, G and QG)

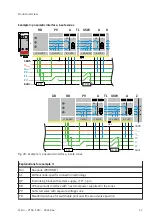

4.3.2

Reverse operation

The supply duct and the exhaust air ducts are interchanged during reverse operation of the valve

terminal:

–

Compressed air supply via duct (3/5)

–

Exhausting via duct (1)