RESET AIRFLOW BASELINES

The airflow baselines can be reset through the LCD screen on FAAST’s user

interface. Selecting this option will cause the FAAST unit to enter in to a five

minute baseline period, which will be displayed on the LCD user interface,

and reset its current air flow baselines.

WARNING

If a high or low condition exists perform a visual inspection of the pipe net-

work to ensure the integrity of the pipe network and that the flow condition is

not caused by breakages or blockages.

ISOLATION

From Normal Mode, Isolation mode is initiated through PipeIQ mimic tab or

through the LCD interface. The device will set the isolation relay and the

isolation fault will be shown on the user interface. The alarm and fault re-

lays will reset and subsequently not change state. In all other respects, the

unit will continue to operate normally. Any smoke exceeding alarm thresholds

will cause alarm conditions to appear on the detector’s front panel, but the

alarm condition will not be communicated to an attached system such as a

fire panel. The device will remain in this mode until it is explicitly removed by

the user, even in the event of power loss or reset.

DISABLE MODE

The user can initiate Disable Mode through the LCD interface only. When

Disable Mode is activated, the device will set the isolation relay and the user

interface will display the disable fault. In Disable Mode, the fan will cease

operation and the particulate, alarm and airflow displays on the user interface

will not be illuminated. The alarm and fault relays will reset and subsequently

not change state. This mode should only be used when the system needs to

be taken offline. This mode is active indefinitely until the user removes the

device from disable mode. All communication interfaces remain active when

the device operates in this state.

ACCLIMATE MODE

The FAAST system includes an available Acclimate mode. By allowing the de-

vice to operate in Acclimate mode, a device’s susceptibility to nuisance alarms

can be reduced. This provides maximum protection for a device located in

changing environments. The sensitivity of the unit continuously adjusts over

time, within user defined limits, as the environment changes. Acclimate mode

must be activated and configured with the PipeIQ software. In Acclimate

mode the device automatically adjusts the alarm point between a specified

minimum and maximum sensitivity, programmed by the user. For the first 24

hours of operation the device monitors the environment. After the initial 24

hour period, the device adjusts the alarm point based on the particulate levels

over a rolling 1 hour period. It then adjusts the alarm level starting from the

insensitive boundary, based on the stability of the environment being moni-

tored.

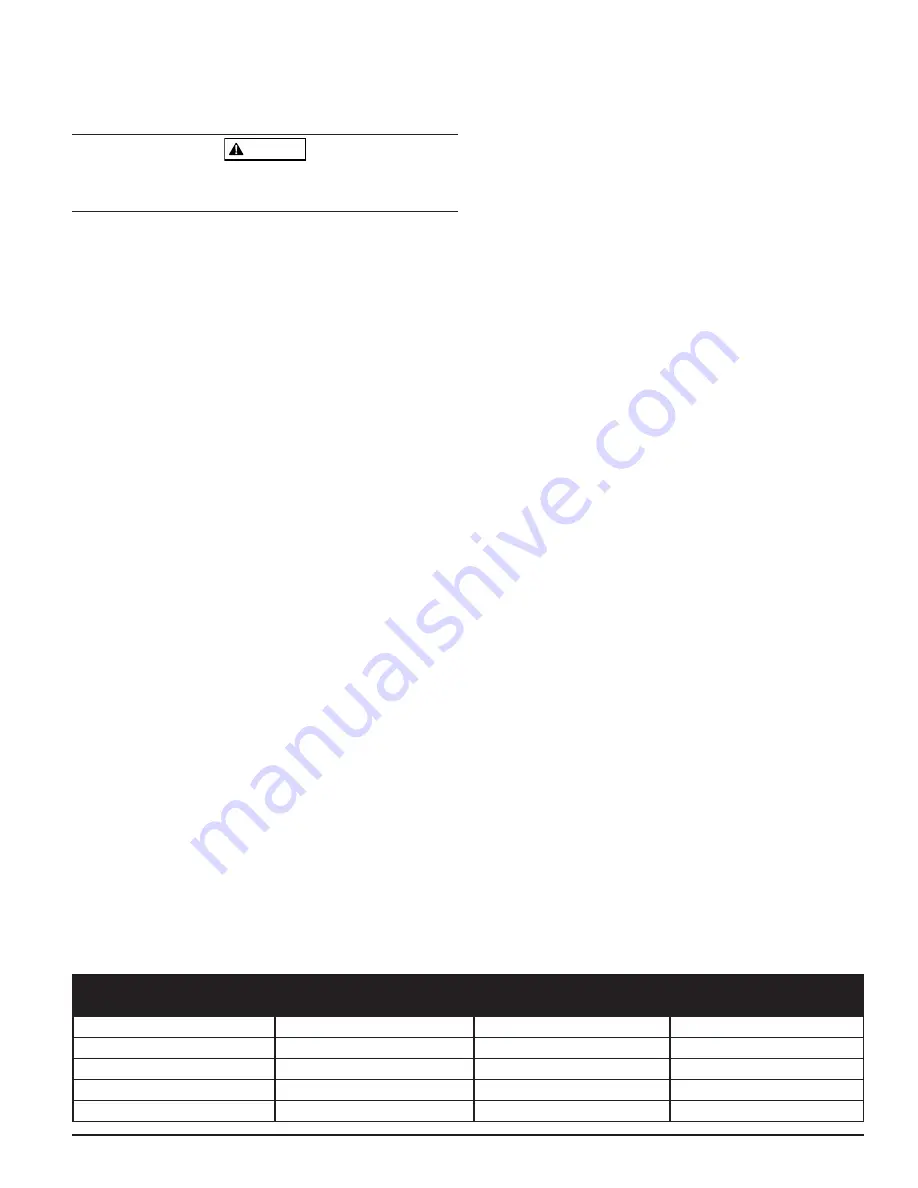

SETTING ACCLIMATE MODE

The user chooses the boundaries for each alarm level in the Acclimate mode.

The FAAST system starts from the insensitive boundary and adjusts itself to

stay within the sensitive boundary. It is also possible to have static alarm lev-

els by adjusting the high and low boundary to the same level. This allows the

felixibility to maintain acclimating levels for some alarms and static levels for

others. Table 6 shows the various levels that are available.

Each Acclimate level is also able to be monitored in PipeIQ. This allows the

user to read the current Acclimated alarm level for each alarm.

ALARM LEVEL

THRESHOLD HIGH

SENSITIVITY

THRESHOLD LOW

SENSITIVITY

CURRENT LEVEL

Alert

Alert High

Alert Low

Acclimate Alert Level

Action 1

Action 1 High

Action 1 Low

Acclimate Action 1 Level

Action 2

Action 2 High

Action 2 Low

Acclimate Action 2 Level

Fire 1

Fire 1 High

Fire 1 Low

Acclimate Fire 1 Level

Fire 2

Fire 2 High

Fire 2 Low

Acclimate Fire 2 Level

DAY, NIGHT AND WEEKEND MODE

If Acclimate mode is not desired, the FAAST system can operate in a simple

day, night and weekend mode. This allows the device to have separate thresh-

old levels for each state. Times can be configured, if desired, for entering and

leaving the day and night time operation. The device has an internal time ref-

erence (clock) and automatically switches to the weekend mode for Saturday

and Sunday.

LOGS

EVENT LOG

The FAAST system is equipped with internal memory that can be configured to

log detector events. Up to 18000 events can be stored. Events that are tracked

include alarms, faults, and user actions. Event tracking may be accessed via

the network through the PipeIQ software or the web server interface. Configu-

ration and management of the log are done using the PipeIQ software.

DATA TREND LOG

The FAAST system can track data from its various sensors in the trend log.

Using PipeIQ the frequency of which the data is recorded can be selected to

allow higher resolution. The rate is limited to a range of 1 to 60 minute or 1 to

24 hour periods. Depending on the rate chosen, data can be collected for 72

hours up to 11.8 years.

MESSAGE LOG

The message log allows the user to enter generic text messages into the de-

vice’s storage memory. Messages may be retrieved for viewing at a later time.

These messages may be used to track service history, configuration changes,

etc. A maximum of 300 messages may be stored.

EXTERNAL MONITOR/RESET

The FAAST system has an external monitor that can detect an open or a short

when the supplied 47 K-ohm end of line resistor is used. When the device

senses an open circuit it sets the External Monitor fault indicator and sets the

Minor fault relay. When a short circuit is detected the device performs a Reset.

This provides the ability to reset alarm latches remotely.

ETHERNET CONNECTION

The FAAST system is a network capable device that is compatible with standard

Ethernet networking equipment. Connectivity is provided by an onboard RJ-45

connector located on the bottom of the unit. The network interface is required

for initial detector configuration. Once initial setup is complete, the Ethernet

connection provides optional remote access, monitoring and e-mail notification

through the unit’s Web server and SMTP client.

USB CONNECTION

A USB port is located on the front of the device to allow for configuration and

monitoring through PipeIQ or the retrieval of data from the device.

PIPE NETWORK

The unit can monitor up to 28,800 sq.ft. (approx. 2,676 sq. m) with a properly

designed pipe network. The pipe network must be properly configured using

the PipeIQ software. The pipe network accommodates a maximum single pipe

length of 400 ft. (123 m). The device is capable of both metric 25 mm and IPS

1.05 in. pipe outside diameters without the use of an adaptor. The internal

pipe diameter can range from .591-.827 inches (15-21mm). The pipe must

be installed such that only the top air inlet ports are used or the bottom air

inlet ports are used. It is not recommended to mix sampling from the top and

bottom ports. Pipe networks may be constructed of various materials such as

ABS, cPVC, PVC, copper or stainless steel pipe. Travel time from the furthest

hole depends on the application of the device, but is limited to a maximum of

120 seconds by the PipeIQ software. Refer to local agency requirements and

PipeIQ software for proper configuration.

TABLE 6. ACCLIMATE LEVELS

11 ASUG56601

firealarmresources.com