9. Commissioning the engine

Overview

Before commissioning the engine read the Rotax Installation Manual again to make quite sure that

nothing has been omitted. At this stage the throttle 100% setting will be established. There are

several other checks that need to be made as part of commissioning the engine. You need to be sure

that there are no restrictions in the oil lines or the fuel lines, and that the engine oil system is fully

primed before first start up. You also need to check that both the electric pumps provide sufficient

flow to the carburettors.

Note:

Refer to the Final Inspection Checklist in appendix A before commencing commissioning.

A limited amount of test equipment is necessary for commissioning, and a kit is available from

Europa Aviation on hire to carry it out.

Throttle setting

The engine is fitted with a 9 pole RS232 plug; this has to be connected via a special cable with a

“dongle” to a PC. More recently Rotax have removed the requirement for a special cable, and a

conventional RS232 connector cable can be used. On earlier engines the part number on the TCU

will be 966471, 966472 or 966473; these engines have a TCU at rev.4.5 and a dongle will be

required: the appropriate software is 4.5. Newer engines have a TCU part number 966741- a dongle

is not required and the TCU and software are at rev. 4.6. The software required must be installed in

the PC. The cable and software are available on hire from Europa.

With the master switch of the aircraft on, run the program - detailed instructions are included in the

Rotax Installation Manual. This will check that the throttle in the closed position corresponds to 0%,

in the fully open position corresponds to 115%, and will enable you to mark the 100% position.

It is recommended that you make a gate or detent at the 100% position to avoid the possibility of

exceeding this power setting in normal flight.

Coolant system

Fill the system with a 50/50 mixture of a good quality antifreeze and water.

Oil system

It is necessary to check that the suction at the oil pump inlet is not excessive. Rotax specify a

maximum depression of 0.3 bar (4.4 psi) below ambient pressure at the oil pump inlet at full throttle.

To check this a ‘T’ piece must be inserted into the oil pump suction line. Because this test has to be

done with the engine running at full throttle it will be carried out later.

Page 9 - 1

Europa XS Rotax 914 Engine Manual

Issue 5

September 2002

Содержание Rotax 914

Страница 1: ...Europa XS Rotax 914 Installation Manual Europa XS Rotax 914 Engine Manual Issue 7 October 2004 ...

Страница 14: ...INTENTIONALLY BLANK Page 2 6 November 2007 Issue 10 Europa XS Rotax 914 Engine Manual ...

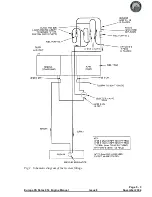

Страница 24: ...Page 4 8 September 2001 Issue 4 Europa XS Rotax 914 Engine Manual Fig 9 Schematic view of oil cooling system ...

Страница 28: ...Page 5 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual Fig 2 Fuel system ...

Страница 32: ...INTENTIONALLY BLANK Page 6 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual ...

Страница 39: ...Page 8 5 Europa XS Rotax 914 Engine Manual Issue 6 September 2003 Fig 2 Propeller and spinner assembly ...

Страница 40: ...INTENTIONALLY BLANK Page 8 6 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...

Страница 44: ...INTENTIONALLY BLANK Page 9 4 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...