Fit the engine mounting frame to the Rotax ring mount using M10 x 110 bolts and M10 Binx nuts.

The upper bolts and the lower port bolt should be fitted with the bolt heads aft, and the lower

starboard bolt with the head forward. The excess length of the bolts will need to be cut off, leaving a

minimum of two threads emerging from the end of the nut. It will be necessary to chamfer the lower

starboard bolt’s head as shown in figure 2.

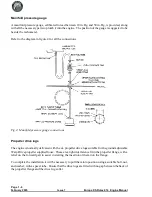

Engine installation

Mount the engine to the landing gear frame using the rubber mountings. See figure 2

To check the orientation of the engine, set the fuselage level using the port door sill as the reference as

usual. Check that the propeller flange is truly vertical.

The engine mounting frame has been designed with the engine offset to starboard by 1.5° To check

that this offset is correct clamp a straight edge to the propeller flange horizontally and mark a point

51 cm (20") each side of the engine centre line. Measure the distance from these points, parallel to the

aircraft centre line, to the firewall. The difference between the two readings should be 26 mm

(1-1/16"). If any correction is found necessary, shim between the landing gear frame and the

appropriate cup washer using AN960-516L washers. In order to ensure that the split pin is correctly

positioned relative to the castellated nut it will be necessary to use a total of at least 4 washers on each

bolt. Any washers that are not needed to act as positioning shims should be placed immediately

under the nut. Make a note of where and how many shim washers are used for later reference.

Note:

The 4 AN5-41 mounting bolts must be tightened fully to compress the rubber anti-vibration

mounts (MT04) onto the steel spacers (MT03).

Caution

:

It should be noted that before the two ignition leads which come from the ignition box are

earthed, the ignition is ”live”. Even though the engine speed must be at least 1200 rpm for the

ignition to fire, it would be a sensible precaution to fit the magneto switches before further work is

carried out on the engine, or at least temporary earth leads connecting the ignition wires to the

engine casing.

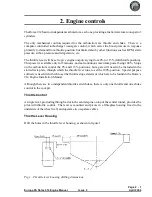

Wastegate control

The turbocharger wastegate is controlled by the TCU and operated by the servo motor unit. These

two items have to be positioned away from sources of high temperatures. Consequently they are to

be fitted in the cabin on the top of the tunnel right at the front behind the firewall.

Servo motor

The servo motor is mounted horizontally on the right of the tunnel, with the operating cable facing

forwards. The positions shown in figure 3 are suggested but, depending on the equipment in the

instrument panel, you may have to site them elsewhere.

Be careful to take into account the length of the already made up cables which connect the various

engine related components together before making your final decision on their positions.

Page 1 - 2

June 2004

Issue 7

Europa XS Rotax 914 Engine Manual

Содержание Rotax 914

Страница 1: ...Europa XS Rotax 914 Installation Manual Europa XS Rotax 914 Engine Manual Issue 7 October 2004 ...

Страница 14: ...INTENTIONALLY BLANK Page 2 6 November 2007 Issue 10 Europa XS Rotax 914 Engine Manual ...

Страница 24: ...Page 4 8 September 2001 Issue 4 Europa XS Rotax 914 Engine Manual Fig 9 Schematic view of oil cooling system ...

Страница 28: ...Page 5 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual Fig 2 Fuel system ...

Страница 32: ...INTENTIONALLY BLANK Page 6 4 November 2004 Issue 8 Europa XS Rotax 914 Engine Manual ...

Страница 39: ...Page 8 5 Europa XS Rotax 914 Engine Manual Issue 6 September 2003 Fig 2 Propeller and spinner assembly ...

Страница 40: ...INTENTIONALLY BLANK Page 8 6 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...

Страница 44: ...INTENTIONALLY BLANK Page 9 4 September 2002 Issue 5 Europa XS Rotax 914 Engine Manual ...