46

CS - 3/16 (4.8)

150

160 (4.1) 3/8 (9.6)

1/8 (3.2)

143

Air - 25 (1.7)

Air - 50 (3.45)

Air - 85 (5.86)

CS - 1/4 (6.4)

140 (3.6)

145

Air - 55 (3.8)

CS - 3/8 (9.6)

90 (2.3)

3/16 (4.8)

156

CS - 1/2 (12.7)

75 (1.9)

1/4 (6.4)

160

Air - 65 (4.48)

CS - 5/8 (15.8)

50 (1.3)

1/2 (12.7)

164

CS - 3/4 (19)

45 1.1)

3/8 (9.6)

179

CS - 1 (25.4)

25 (.64)

184

SS - 3/16 (4.8)

150

200

3/8 (9.6)

1/8 (3.2)

138

Air - 25 (1.7)

Air - 50 (3.45)

Air - 85 (5.86)

SS - 1/4 (6.4)

165

3/16 (4.8)

146

Air - 65 (4.48)

SS - 3/8 (9.6)

95

1/4 (6.4)

155

SS - 1/2 (12.7)

60

5/16 (8)

163

SS - 3/4 (19)

25

1/2 (12.7) 3/8 (9.6)

175

SS - 1 (25.4)

15

185

AL - 3/16 (4.8)

150

200 (5.1) 3/8 (9.6)

3/16 (4.8)

148

Air - 25 (1.7)

Air - 45 (3.1)

Air - 85 (5.86)

AL - 1/4 (6.4)

140 (3.6)

149

AL - 3/8 (9.6)

105 (2.7)

1/4 (6.4)

159

Air - 65 (4.48)

AL - 1/2 (12.7)

80 (2)

5/16 (8)

174

Air - 85 (5.86)

AL - 3/4 (19)

45 (1.1)

1/2 (12.7)

180

Air - 65 (4.48)

AL - 1 (25.4)

30 (.76)

184

CS - 3/16 (4.8)

150

160 (4.1) 3/8 (9.6)

1/8 (3.2)

127

N

2

- 25 (1.7)

O

2

- 45 (3.1)

Air

- 85 (5.86)

CS - 1/4 (6.4)

150 (3.8)

3/16 (4.8)

130

Air - 45 (3.1)

CS - 3/8 (9.6)

90 (2.3)

134

Air

- 65 (4.48)

CS - 1/2 (12.7)

75 (1.9)

1/4 (6.4)

142

CS - 5/8 (15.8)

55 (1.4)

1/2 (12.7) 5/16 (8)

151

Air

- 85 (5.86)

CS - 3/4 (19)

45 (1.1)

3/8 (9.6)

157

Air - 65 (4.48)

CS - 1 (25.4)

25 (.64)

5/16 (8)

160

seCtIon 4

operatIon

4.4.3.4 process Data at 150 amps (pt-19xls and pt-600)

Current

(amps)

pierce

height

in.(mm)

Cutting

height

in.(mm)

arc

Voltage

(Volts)

travel

speed

ipm(M/m)

Material

type-thickness

in. (mm)

start gas

type/pressure

psi(bar)

shield gas

type/pressure

psi(bar)

plasma gas

type/pressure

psi(bar)

NOTES: When using a 50 ft torch, a dwell of approx. 3 sec. is required to allow the N

2

start gas to be purged out by the O

2

cut gas.

CS - Carbon Steel, SS - Stainless Steel, AL - Aluminum

All Air Plasma/Air Shield, 100 Amp cuts on Aluminum have good surfaces except 3/4” (19mm) AL that has poor surface.

All Air Plasma/Air Shield, 100 Amp cuts on Stainless Steel have fair surface except 3/4” (19mm) SS that is very rough.

All N

2

Plasma/N

2

Shield, 100 Amp cuts on Stainless Steel have fairly good surfaces except 3/4” (19mm) SS that is fair.

Pilot Arc -- HIGH

Содержание ESP-200

Страница 1: ...ESP 200 Plasmarc Cutting System Instruction Manual F15 462 C 02 2008 ...

Страница 12: ...12 section 2 description ...

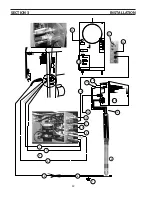

Страница 31: ...31 section 3 installation Plumbing box fully connected including setup pendant ...

Страница 32: ...32 CE 1 2 3 4 5 6 7 9 10 11 12 13 16 19 20 21 22 15 17 18 14 section 3 installation 8 ...

Страница 78: ...78 section 7 replacement parts 7 3 ESP 200 P N 36324 Outside View Front 1 2 3 4 5 6 7 8 9 10 11 12 ...

Страница 80: ...80 section 7 replacement parts 7 4 Outside View Back CE 1 2 3 4 5 6 7 8 9 10 11 CE Unit Only 12 13 ...

Страница 84: ...84 section 7 replacement parts 1 2 3 4 5 6 7 8 9 10 11 12 13 7 6 Right Inside View ...

Страница 88: ...88 section 7 replacement parts 6 1 4 5 6 R ef R ef 2 3 7 8 Back and Top Inside View ...

Страница 92: ...92 section 7 replacement parts 1 2 3 4 5 6 7 8 7 10 Remote Setup Pendant P N 37145 ...

Страница 100: ...100 notes ...