21

seCtIon 3

InstallatIon

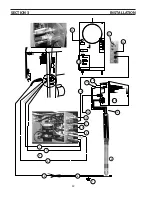

7. Connect the other end of work cable to workpiece or cutting table. Connection must be made to a clean, exposed

metal surface, free of paint, rust, mill scale, etc.

Work ground to work piece

Work ground to cutting table

eleCtrIC Current Is haZarDous.

It Is IMportant to haVe a gooD earth grounD ConneCteD

to the WorKpIeCe or CuttIng taBle.

WarnIng

Commercial antifreeze Will Cause torch to Malfunction.

use special torch coolant. p/n 156F05

Due to high electrical conductivity, Do not use tap water or com-

mercial automotive type antifreeze for torch cooling. a specially

formulated torch coolant is requIreD. this coolant also protects

from freezing to –34 degrees C. operating the unit without coolant

will cause permanent damage to the coolant pump. Check coolant

level frequently.

CautIon

8. Remove coolant fill cap at front console and fill coolant tank with 4

gallons (15 liters) of plasma torch coolant, P/N 156F05 (one gallon).

Do not fill above indicated maximum level.

•

Reinstall cap.

•

Coolant Fill Cap

Содержание ESP-200

Страница 1: ...ESP 200 Plasmarc Cutting System Instruction Manual F15 462 C 02 2008 ...

Страница 12: ...12 section 2 description ...

Страница 31: ...31 section 3 installation Plumbing box fully connected including setup pendant ...

Страница 32: ...32 CE 1 2 3 4 5 6 7 9 10 11 12 13 16 19 20 21 22 15 17 18 14 section 3 installation 8 ...

Страница 78: ...78 section 7 replacement parts 7 3 ESP 200 P N 36324 Outside View Front 1 2 3 4 5 6 7 8 9 10 11 12 ...

Страница 80: ...80 section 7 replacement parts 7 4 Outside View Back CE 1 2 3 4 5 6 7 8 9 10 11 CE Unit Only 12 13 ...

Страница 84: ...84 section 7 replacement parts 1 2 3 4 5 6 7 8 9 10 11 12 13 7 6 Right Inside View ...

Страница 88: ...88 section 7 replacement parts 6 1 4 5 6 R ef R ef 2 3 7 8 Back and Top Inside View ...

Страница 92: ...92 section 7 replacement parts 1 2 3 4 5 6 7 8 7 10 Remote Setup Pendant P N 37145 ...

Страница 100: ...100 notes ...