2.1.3 Reference to safety measures for specific

operating conditions

2.1.3.1 Safety measures

•

The tow plate of the spreader must be vertical when the

vehicle is loaded.

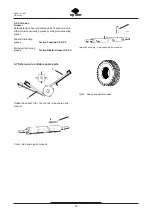

• The draw bar is adjustable for height as well as length.

Important: When adjusting height, self-locking nuts (A)

must only be used once, i.e. always use new self-

locking nuts. Nut (M14 DIN 985 A2) torque must be

120 Nm.

• The stabiliser/supporting leg facilitates

connection/disconnection of the spreader. Before dri-

ving, the driver must check that the stabiliser/supporting

leg has been lifted.

•

The depth of the tyre tread pattern must be min. 1.6 mm.

For information on air pressure in the road tyres.

2.1.3.2 Work safety

• Protection devices: The equipment must not be

operated without protection devices.

• The drawbar position must not be above hori-

zontal position due to the risk of tipping.

See section 2.1.2 Total weight reference – support load.

• Driving gear: The warranty and liability become void if

changes are made to the driving gear.

• Oblique position: The road may have a maximum incli-

nation of 10%.

• The spreader must only be subjected to repair work

when the motor of the towing vehicle has been stopped.

• Following repair work, all safety devices must be conne-

cted to the spreader.

• Unauthorised persons are to be turned away from the

danger zone.

• Persons must not be in the immediate proximity of the

machine (1 m to the side of the machine) when the

machine is operating.

•

Notice!

- Only spare parts recommended by the manu-

facturer must be used.

2.1.3.3 Before driving

Before starting, the driver should check that:

• the tow plate of the spreader must be vertical

when the vehicle is loaded.

• the spreader’s towbar is correctly positioned and secu-

red to the tow-bar on the vehicle.

• the stabilizers have been raised.

• the safety devices are functioning.

• electrical connections and power supply have been con-

nected.

• the lights are functioning.

•

the operating device has been fitted.

•

the air pressure in the tyres is correct.

Remember to check adjustments.

2.1.3.4 Safety during cleaning, repairs and main-

tenance

• When cleaning, repairs, maintenance and similar

work is performed on the spreader, the motor of

the towing vehicle must be stopped.

• Intervals of maintenance are divided into operating

hours and apply to normal operating terms.

•

Please observe the specified intervals of maintenance.

•

See the maintenance and inspection list.

•

Only the spare parts approved and recommended by

the manufacturer must be used.

Please use the original Epoke-spare parts only.

•

After repair, safety devices must be correctly fitted

again.

•

It is not allowed to drive without safety devices.

6

epoke

®

SKE8-12-15-20

GB-0305.1

epoke

®

Содержание SKE Series

Страница 2: ......

Страница 10: ......

Страница 12: ...9 epoke SKE8 12 15 20 GB 0305 1 2 2 4 6 7 8 9 10 1 2 3 4 5 C B A C D...

Страница 26: ...23 epoke SKE8 12 15 20 GB 0305 1 8 1...