10

epoke

®

SKE8-12-15-20

GB-0305.1

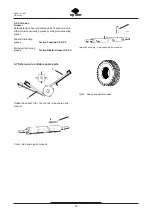

2.2.4 Metering system

1

The Epoke principle

A - Impellor shaft with springs

B - Delivery roller with cams

C - Rubber base

D - Spring base

2

The impellor shaft pulverizes all lumps, distributes the

spreading material in the whole length of the hopper,

and ensures constant supply to the delivery roller.

Impellor springs: When replacing defect impellor

springs, the flat side is to point to the front in working

direction and be placed in two spirals, which start in

the centre, whereby the material is lead towards the

centre. Start with no. 1 in the middle. Turn the tube

1/4 turn forward in the working direction, mount pair

no. 2 equally on each side of no. 1. Turn 1/4 turn in

the working direction, mount pair no. 3 equally on

each side of the previously mounted pair etc.

3

Possibility for demounting defect impellor springs.

4

The delivery roller is provided with cams (A) which

bring the material through the spring adjusted rubber

base. The cams are available in different designs for

all types of material and dosages.

Great and many cams: Great amount (sand etc).

Small and less cams: Small amount (salt).

5

The delivery cams: If the cams are worn, they are to

be replaced. If the screws are rustbound, the cams

can be blasted with a hammer, and the screws be

loosened with tongs. To ease a replacement of cams

later, it is recommended to fill in approx. 1/4 l waste

oil into the delivery roller. This has not been done

from the works out of regard for the oil waste during

shipment.

6

The rubber bases are jammed under the clamping iron

and can be turned and worn on all edges provided that

they are turned in time, see also description of the

spring base.

7

The spring base presses the bottom rubber base

against the cams of the delivery roller, regulated by

the spring base adjustment. Defect springs by wea-

ring are to be replaced. When the spring base is

open, all points of the springs are to be in line.

The spring base stop is adjustable and placed in

order to stop the movement of the spring base for

max. material quantity.

8

Spring base adjustment: The adjustment is obtained

by the pressure of the bottom rubber base with diffe-

rent strength against the delivery roller by means of

the spring base. The pressure is varied by the adjust-

ment handle at the rear of the spreader.

Содержание SKE Series

Страница 2: ......

Страница 10: ......

Страница 12: ...9 epoke SKE8 12 15 20 GB 0305 1 2 2 4 6 7 8 9 10 1 2 3 4 5 C B A C D...

Страница 26: ...23 epoke SKE8 12 15 20 GB 0305 1 8 1...