15

epoke

®

SKE8-12-15-20

GB-0305.1

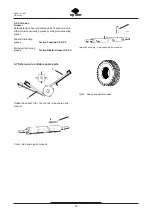

5.12 Instructions for repair and assembly

Replacement of delivery roller and impellor

The shafts are drawn sidewards out of the rear plates of the

hopper. The holes are big enough to let through the delivery

roller and the impellor mounted with cams and springs.

Remember to loosen both allan screws in the flange bea-

rings when the delivery roller and the impellor are dismoun-

ted. When mounting the delivery roller and the impellor the

tallow string tightenings are to be connected carefully and

the shaft ends to be wiped and greased. The chain wheels

must also flush.

6 Maintenance

6.2.1 Cleaning

All Epoke spreaders have been sandblasted, zinc dust

primed and primed before being painted with laquer, and

they are therefore extremely well-protected against rust.

However it is recommended - espescially after spreading

salt and if there are longer pauses between operations -

that the spreader is washed down with water after use.

Regular control extends the lifetime of the spreader and

guarantees a safer function.

6.2.2 Maintenance

Cleaning remote control.

Clean the remote control with a slightly moistened cloth

and wipe with a dry cloth.

Maintaining remote control.

Connectors and strain reliefs should be checked at regu-

lar intervals or at least every 100 operating hours. Defect

connectors must be replaced.

All moving transmission parts and bearings should be

lubricated with grease, see inspection list - mechanical

item 6.3.1.

The driving shafts

are suspended in spherical roller bea-

rings with tightenings and in flange bearings. They should

be greased only once a year. Over-greasing may spoil the

tightenings. Likewise too much grease may cause the

bearings to overheat.

Delivery roller and impellore

are suspended in flange

bearings by a laminated tightening. The bearings are gre-

ased at the factory and do not need much greasing, but

for the sake of the tallow tightenings mounted behind a

frquent greasing is recommended, at least after each 25

hours ‘ operating.

Spring base adjustment

is lubricated through the lubri-

cation nipple with grease, see inspection list - mechanical

item 6.3.1

Defect cams

are to be replaced. If the screws are rustbo-

und, the cams can be blasted with a hammer, and the

screws can be loosened with tongs. In order to avoid this,

it is recommended, before use to loosen a cam and fill in

approx. 1/4 litre waste oil in the delivery roller.

Impellors:

Defect springs are to be replaced, see mete-

ring system item 2.2.4.

Spring base:

Defect springs are to be replaced. When

the spring base is wide open, the points of the springs

must be in line.

Rubber base:

The rubber bases are wedged in under

clamping iron and can be turned and worn on all 4 edges,

provided that they are turned in time.

Roller chains:

Control that they are tightened. They shall

be tightened in such a way that they by means tightening

them totally.

Clutch:

Free function is checked. Otherwise clean and gre-

ase all parts. When the spreader is engaged is engaged the

pawl chamber, the pawl retainer and the pawl must turn free

without touching the stripper. When the spreader is disenga-

ged the pawl must be combletely in bottom.

6.2.3 Storing

After the winter season it is recommended that the sprea-

der is cleaned, protected against corrosion, lubricated and

has damages in the laquer repaired.

The spreader must be stored with an open (completely

open) spring base.

Storing remote control

When not in use, the remote control should be stored in a

dry place.

5.11 Procedure in case of failure

Problems

Cause

Remedy

1. Electric remote control out of order

1a. No power

1a. Connect power

1b. Fuse blown

1b. Replace the fuse

2. The spreader does not start

2a. No power on the system

2a. See item 1.

when using the remote control

2b. Bad connection in the 4-poled plug

2b. Clean/replace the plug

2c. Engine defective

2c. Replace engine

3. The spreader does not start manually

3a. Scraper does not move/

3a. Check connections to start/stop

eccentric does not turn

handle/axle (tailstock screw has

come loose – tighten)

3b. Chain broken

3b. Mount a new chain

4. Defective light/indicator

4a. No power

4a. Check connections

4b. Bad connection in the 7-poled plug

4b. Clean/replace the plug

4c. Bulb broken

4c. Replace bulb

Содержание SKE Series

Страница 2: ......

Страница 10: ......

Страница 12: ...9 epoke SKE8 12 15 20 GB 0305 1 2 2 4 6 7 8 9 10 1 2 3 4 5 C B A C D...

Страница 26: ...23 epoke SKE8 12 15 20 GB 0305 1 8 1...