4

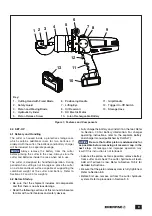

Max Diameter Alert:

Cutting diameter must not

exceed 20 mm [0.79 inch].

PPE Alert:

Wear personal

protective equipment

(PPE) when using or

servicing equipment

Instruction Manual Alert:

Read the

instruction manual before using or servicing

equipment.

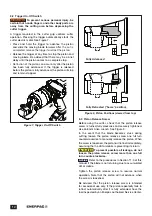

1.7 Crush Hazard

DANGER

Cutter will start immediately when

battery is installed on cutter and on-off trigger is

depressed.

DO NOT place hands, fingers or other parts of your

body inside the cutting head unless battery is

removed from cutter. Death or serious personal

injury will result if cutter is started while persons are

working inside the cutting head.

• Never reach into the cutting head while cutter is in

operation.

• Before reaching inside the cutting head for any

reason, always stop the cutter and remove battery.

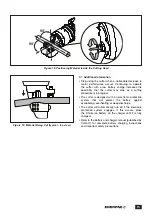

been dropped, run over, or damaged in any way (e.g.,

pierced with a nail, hit with a hammer, stepped on,

etc.). Damaged batteries should be properly recycled

or disposed of, in accordance with all applicable laws

and regulations in your country or region.

• Do not store or carry the battery so that metal objects

can contact exposed battery terminals.

• Refer to manufacturer’s battery and charger manual

for complete safety precautions, use and disposal

instructions, and transport instructions.

• Use the cutter only with a compatible battery of

original equipment specifications. Use of a non-

compatible battery may result in erratic and/or unsafe

operation.

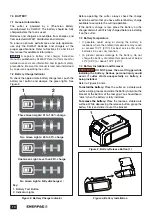

1.5 Lithium-ion Batteries - Additional Safety

Information

NOTICE:

DANGER

Failure to observe and comply with the

following precautions will result in death or serious

personal injury. Property damage could also occur.

• Do not incinerate the battery even if it is severely

damaged or completely worn out.

The battery

can explode in a fire. Toxic fumes and materials are

created when lithium-ion batteries are burned.

• If battery contents come into contact with the

skin, immediately wash area with mild soap and

water.

If battery liquid gets into the eye, rinse water

over the open eye for 15 minutes or until irritation

ceases. If medical attention is needed, note that the

battery electrolyte is composed of a mixture of liquid

organic carbonates and lithium salts.

• Contents of opened battery cells may cause

respiratory irritation.

Provide fresh air. If symptoms

persist, seek medical attention.

1.6 Safety Symbols (on cutter)

WARNING

Failure to observe and comply with the

safety symbols affixed to the cutter housing could

result in death or serious personal injury.

WARNING

Make sure the safety symbols (decals,

labels, etc.) are securely affixed to the tool and that

they are legible. If not, obtain replacements from

Enerpac. Refer to tool repair parts sheet for locations

and part numbers. Failure to maintain safety symbols

on tool could result in death or serious personal

injury.

The following safety symbols are affixed to the cutter

housing:

Crush hazard:

Keep hands, fingers and other

body parts away from the cutting head.

Projectile hazard:

Objects may be ejected

from the cutter during operation. Stay clear of

cutting area. Wear eye and face protection.

Содержание EBC20B

Страница 25: ...25 Notes...

Страница 26: ...26 Notes...

Страница 27: ...27 Notes...

Страница 28: ...199 Gateway Ct Columbus WI 53925 USA www enerpac com Made in Italy WWW ENERPAC COM...