TMT182

1 Safety notes

Hauser

11

3.2.2

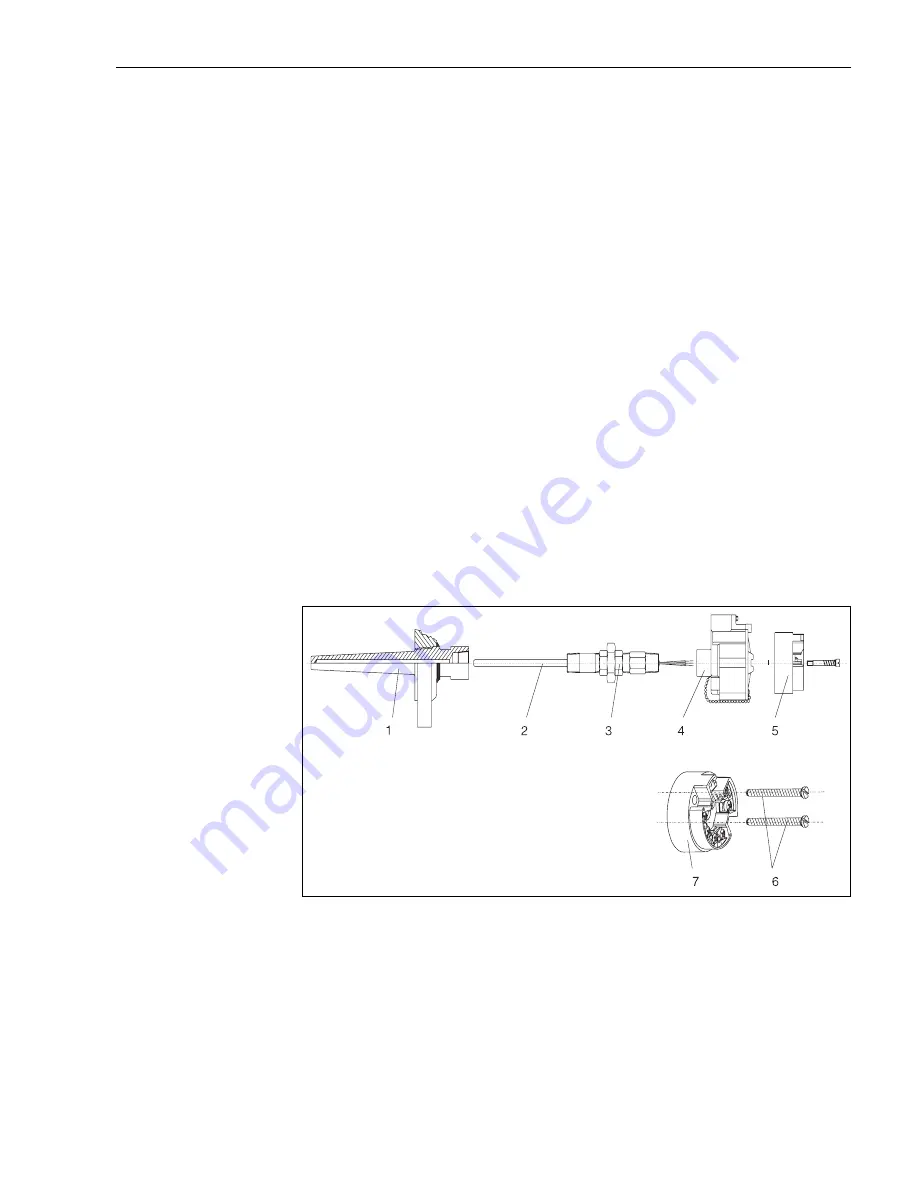

Typical North American installation

Industrial thermocouple or RTD assembly with head transmitter (see fig. 5)

• Attach the thermowell (Pos. 1) to the pipe or process container wall. Install and tighten thermo-

wells before applying process pressure.

• Attach necessary extension nipples and adapters (Pos. 3) to the thermowell. Seal the nipple and

adapter threads with silicone tape.

• Install drain seals if required for severe environments or to satisfy code requirements.

• Feed the installation screws (Pos. 6) through the holes in the head transmitter (Pos. 7).

• Position the head transmitter assembly in the transmitter housing (Pos. 4) in such a way so that

the current output terminals (terminal 1 and 2) are towards the conduit.

• Screw the head transmitter assembly (Pos. 5) into the the transmitter housing (Pos. 4) using a

screwdriver.

• Feed the sensor inset cables through the conduit of the transmitter housing and the central hole

in the head transmitter.

• Attach the transmitter housing (Pos. 4) with built in head transmitter assembly to the nipples and

adapters (Pos. 3). Seal adapter threads with silicone tape.

"

Caution!

In order to avoid damaging the head transmitter, do not over-tighten the installation screws.

"

Caution!

Pull the field wiring leads through the conduit into the transmitter housing. Attach the sensor and

power leads to the head transmitter. Avoid contact with other terminals.

"

Caution!

Install and tighten the transmitter housing cover. Enclosure covers must be fully engaged to meet

explosion-proof requirements.

ƒig. 5:

: Installing the head transmitter - Head transmitter assembly

Pos. 1: Thermowell

Pos. 2: Measuring inset

Pos. 3: Extension neck

Pos. 4: Transmitter housing

Pos. 5: Head transmitter assembly

Pos. 6: Installation screws

Pos. 7: Head transmitter