4 – 4

Section 4 • Operation

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

• The range of travel is not correct and the command

shaft travel is physically correct.

• The compressor is pulling high amperage, the cali-

bration of the volume slide should be checked.

• An actuator does not unload below 5%, or an actua-

tor that doesn’t move.

• Something is not working properly such as the actua-

tors, RTDs or transducers.

To calibrate optical actuators, continue with the follow-

ing steps:

NOTE

If the compressor unit is starting up for the first

time or a new actuator motor has been installed,

leave the power cable and position transmitter cable

disconnected until step 6.

1. Stop compressor unit and allow to cool.

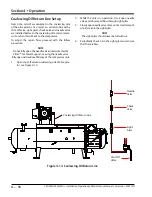

2. Remove screws securing actuator cover to actuator

assembly. As a reference see Figure 4-2.

CAUTION

Wires are attached to the connector on the actuator

cover. Handle actuator cover with care to prevent

damage to wires. Failure to comply may result in

damage to equipment.

Blue Calibrate Button

Red LED

Actuator

Plastic Cover

Actuator

Assembly

Figure 4-2. Actuator Assembly

View Rotate 180°

Calibrate Slide Valve Actuators (For

Units Using Vission20/20™)

1

Slide valve actuators must be installed prior to calibra-

tion. Refer to Slide Valve Actuator Installation proce-

dure. The following steps pertain to calibrating one slide

valve actuator. Repeat procedure to calibrate other slide

valve actuator.

WARNING

After stopping the compressor, allow the compressor

and surrounding components to cool down prior

to servicing. Failure to comply may result in serious

injury.

CAUTION

Do not calibrate in direct sunlight. Failure to comply

may result in damage to equipment.

Both the capacity and volume slide actuators should be

calibrated when one or more of these have occurred:

•

Compressor unit starting up for the first time.

• A new actuator motor has been installed.

•

There is an error code flashing on the actuator’s

circuit board - an attempt to recalibrate should be

made.

1

Does not apply to compressors that operate

without slides (VSM-97, VSM-113, VSM-127).

Содержание Vilter VSH

Страница 2: ......

Страница 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 219: ......

Страница 221: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 249: ......