5 – 30

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

7. Using appropriate drain pan, drain oil by removing

drain plugs from under compressor housing and

discharge manifold. Allow oil to completely drain.

8. Remove all oil lines from the compressor.

9. Support suction line with appropriate supporting

equipment.

10. Remove nuts and bolts securing suction strainer/

check valve assembly to suction stop valve and

compressor.

11. Using appropriate lifting device, remove suction

strainer/check valve assembly from compressor.

12. Remove nuts and bolts securing discharge pipe to

compressor and oil separator, see Figure 5-20.

13. Remove discharge pipe and gaskets from compres-

sor and oil separator.

14.

Remove nuts, flat washers, lock washers and studs

securing compressor to frame.

15. Remove any additional lines and/or components to

allow removal of compressor as required.

NOTE

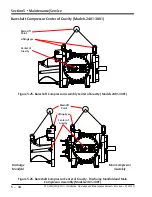

Refer to Bareshaft Compressor Lifting Points and

Weights section for appropriate lifting hole sizes,

weights and lifting points.

16. Install appropriate lifting eyes on top of compressor.

17. Using appropriate lifting device and additional per-

sonnel, remove compressor from frame.

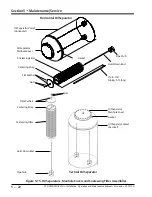

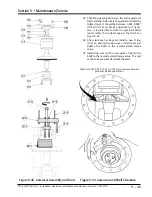

Figure 5-20. Compressor Replacement

and Hardware Assembly

(VSS 2401-3001 Shown)

Nut

Lock Washer

Flat Washer

Spherical

Washer

Assembly

Stud

Flat Washer

Lock Washer

Nut

Shim

Frame

Compressor

Compressor Replacement

Notify Vilter

TM

prior to performing a compressor replace-

ment. See Warranty instructions in Section 7.

Removal

To replace a compressor on a unit, proceed with the fol-

lowing steps:

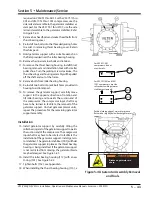

NOTICE

Dispose of used oil in an appropriate manner following

all Local, State and Federal laws and ordinances.

1. Shut down and isolate the compressor unit, see

Compressor Unit Isolation for Maintenance and

Service procedure.

NOTE

Note location of cables to aid in installation.

2. Disconnect all cables from sensors on compressor

and actuators.

3. Remove coupling guard, see Coupling Guard

Replacement procedure.

4. Remove drive coupling, see appropriate Drive

Coupling Replacement procedure.

5. Remove center member, see Drive Coupling

Removal procedure.

NOTE

Use appropriate supporting equipment to support

and keep motor, C-flange and compressor leveled.

6.

If equipped with C-flange, remove bolts securing

C-flange to compressor.

Содержание Vilter VSH

Страница 2: ......

Страница 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 219: ......

Страница 221: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 249: ......