5 – 20

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

Oil Filter Element Removal

(For 3110A OR 3112A Oil Filter Housing - See

Figure 5-14)

13.

Remove oil filter housing cover and O-ring from oil

filter housing. Discard O-ring.

14.

Remove filter element from internal port of head

assembly.

15.

Clean filter element connection area of head as

-

sembly and interior of filter housing and cover.

Oil Filter Element Installation

(For 3111A Oil Filter Housing - See Figure 5-9)

16. Lubricate new O-ring with clean system oil.

17.

Install O-ring on inside of filter head.

18.

Install new filter element on internal port of head

assembly. Make sure filter element is fully seated.

19. Lubricate threads of locking ring with clean system

oil.

20. Hand tighten locking ring only. Install locking ring

and filter housing on head assembly until filter

housing bottoms. Do not overtighten locking ring.

21. Using dry nitrogen gas, pressurize isolated oil line

through bleed valve of filter housing. Check for

leaks on replaced components.

22. Evacuate isolated oil line to 29.88” Hg (1000 mi-

crons) and close bleed valve.

23.

Install plug on bleed valve of filter housing.

24.

Slowly open oil supply valve and allow oil to fill oil

line.

25.

Open filter outlet valve.

26.

Check oil level and fill oil separator to non-operat

-

ing level, see Oil Charging procedure.

Oil Filter Element Installation

(For 3110A OR 3112A Oil Filter Housing - See

Figure 5-14)

27.

Install new filter element on internal port of head

assembly. Make sure filter element is fully seated.

28. Lubricate new O-ring with clean system oil.

29.

Hand tighten oil filter housing cover only. Install

O-ring and oil filter housing cover on oil filter

housing.

30. Using dry nitrogen gas, pressurize isolated oil line

through bleed valve of filter housing. Check for

leaks on replaced components.

31. Evacuate isolated oil line to 29.88” Hg (1000 mi-

crons) and close bleed valve.

32.

Install plug on bleed valve of filter housing.

33.

Slowly open oil supply valve and allow oil to fill oil

line.

34.

Open filter outlet valve.

35.

Check oil level and fill oil separator to non-operat

-

ing level, see Oil Charging procedure.

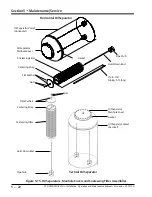

Figure 5-14. Filter Assembly

(VPN 3112A Oil Filter Housing Shown)

Oil Filter Head

Assembly

Oil Filter

Element

Oil Outlet

Connection

Oil Filter

Housing

O-ring

Oil Filter

Housing Cover

Oil Filter Drain

Valve with Plug

Oil Inlet

Connection

Plug

Содержание Vilter VSH

Страница 2: ......

Страница 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 219: ......

Страница 221: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 249: ......