5 – 43

Section 5 • Maintenance/Service

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

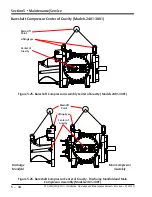

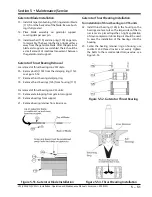

required on VSS 451 thru 601. For the VSS 751 thru

901 and VSS 1051 thru 1301 compressors, use the

side rails and assemble to the gaterotor stabilizer as

stamped. For the VSS 1551 thru 2101, use the side

rails and assemble to the gaterotor stabilizer. Refer

to Figure 5-40.

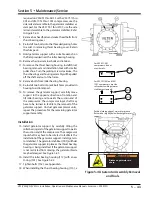

7. Remove hex head bolts and socket head bolts from

thrust bearing cover.

8. Re-install two bolts into the threaded jacking holes

to assist in removing thrust bearing cover. Retain

the shim pack.

9. Hold gaterotor support with a suitable wrench on

the flats provided near the roller bearing housing.

10. Remove the inner retainer bolts and retainer.

11. To remove the thrust bearing housing, install thrust

bearing removal and installation tool with smaller

puller shoe. Turn the jacking screw clockwise. The

thrust bearings and housing assembly will be pulled

off the shaft and out of the frame.

12. Remove bolts from roller bearing housing.

13. Re-install two bolts into jack bolt holes provided in

housing to aid in removal.

14. To remove the gaterotor support, carefully move

support in the opposite direction of rotation and

tilt roller bearing end towards the suction end of

the compressor. The compressor input shaft may

have to be turned to facilitate the removal of the

gaterotor support. On dual gate compressor units,

repeat the procedure for the remaining gaterotor

support assembly.

Installation

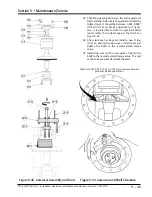

15. Install gaterotor support by carefully tilting the

roller bearing end of the gaterotor support towards

the suction end of the compressor. The compressor

input shaft may have to be rotated to facilitate the

installation of the gaterotor support. Install gatero-

tor stabilizer. The gaterotor stabilizer (901) will hold

the gaterotor support in place as the thrust bearing

housing is being installed. If the gaterotor support

is not restricted from moving, the gaterotor blade

may be damaged. See Figure 5-41.

16. Install the roller bearing housing (112) with a new

O-ring (141). See Figure 5-42.

17. Tighten bolts (152), see Appendix A.

18. When installing the thrust bearing housing (113), a

!

WARNING

Blades on gaterotor are

sharp.

90 1C

90 1B

90 1A

Figure 5-40. Gaterotor Assembly Removal

and Tools

For VSS 451-601

compressors, do not

use side rails.

For VSS 751/901 and 1051-

1301 compressors, use side

rails and assemble gaterotor

stabilizer as stamped.

Position leading edge of main rotor groove

flush with or slightly below back of gaterotor

support.

Содержание Vilter VSH

Страница 2: ......

Страница 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 219: ......

Страница 221: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 249: ......