3 – 21

Section 3 • Installation

VSS/VSM/VSH/VSSH • Installation, Operation and Maintenance Manual • Emerson • 35391SD

Unit Initial Oil Charging

(Reference Figure 3-17)

10. At initial start up, compressor unit must be off and

depressurized prior to initial oil charging.

11. Using a properly selected oil pump, connect oil

pump to oil separator drain valve (10) (for oil sepa

-

rator drain valve location, see Figure 3-16).

12. Open oil separator drain valve (10) and fill oil separa

-

tor (1) to Maximum NON-Operating Level.

13. Once Maximum NON-Operating Level has been

reached, shut off oil pump, close oil separator drain

valve (10) and remove oil pump.

14. If equipped with remote oil cooler, refer to Priming

Compressor Units Equipped with Remote Oil Cooler

procedure (see Appendix G).

Priming Oil Lines and Compressor

Continue with the following steps to prime the oil lines

and compressor:

15. Make sure valves on oil circuit are in the open posi

-

tion. In this case, make sure valves (2), (3), (5), (6)

and (7) are in the open position.

16. Energize compressor unit. Vission 20/20 will ener

-

gize oil heaters.

17. Run oil pump (4) for 15 seconds only.

18. Wait minimum of 30 minutes to allow oil to drain

from compressor (8).

19. If compressor unit is not being started right away,

repeat steps 6 to 9 prior to starting.

Figure 3-16. Oil Drain Valve

Oil Drain Valve

(Oil Separator)

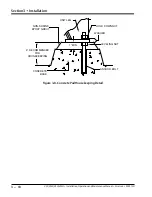

Figure 3-17. Priming Oil Lines and Compressor

LG

001

LG

002

FG

001

PI

003

DRAIN

TW

BLEED

MW

BLEED

TW

D100

OIL CHARGE

BLEED

CAPACITY

TW

750W

TW

250#

C100

V100

VOLUME

SUCTION

STOP VALVE

DISCHARGE STOP VALVE

D101

P100

TW

750W

TW

750W

DRAIN

DISCHARGE CHECK VALVE

PI

002

PI

001

TE

001

TE

004

QE

003

TE

005

PI

004

BLEED

PT

004

PT

003

PT

002

D102

D103

TW

TE

002

QE

001

QE

002

OIL SEPARATOR

COALESCING OIL

RETURN LINE

HIGH PRESSURE

R717 VAPOR OUTLET

R717 VAPOR

TO ATMOSPHERE

LOW PRESSURE

R717 VAPOR INLET

PT

001

COMPRESSOR

MOTOR

FIL

TER

MOTOR AND

OIL PUMP

T

E100

R717 LIQUID

INLET

R717 LIQUID/VAPOR

OUTLET

100

PSID

SUCTION

CHECK VALVE

OPTIONAL

(STANDARD FOR BOOSTER &

SWING COMPRESSORS ONLY)

4

1

10

2

5

3

9

8

7

6

Содержание Vilter VSH

Страница 2: ......

Страница 30: ...2 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 54: ...3 24 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 74: ...4 20 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 144: ...5 70 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 156: ...7 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 158: ...8 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 204: ...8 48 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 206: ...A 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 210: ...B 4 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 216: ...C 6 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 219: ......

Страница 221: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 242: ...E 12 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 248: ...G 2 Blank VSS VSM VSH VSSH Installation Operation and Maintenance Manual Emerson 35391SD ...

Страница 249: ......