Settings

EFORT INTELLIGENT EQUIPMENT CO.,LTD

113

Line 2: The robot moves in a P2P manner to "position 1", i.e., the initial position.

Line 4: Some initial preparation settings, including:

(1) Initialization of the tracking vision function (line 6), and

(2) Acquisition of the data of the axis group named "linearbelt" in the system (line 7),

and

(3) Associating the interrupt variable "intr" with the interrupt response subroutine

"skipmove" (line 8), and

(4) Set the trigger condition of "intr", i.e., when _errno_ ! = 0 (line 9), and

(5) Turn off the interrupt triggering (line 10).

(6) Clear all data in the trace queue (line 11)

Line 13: assignment of the built-in variable wobj_cvy_fixed (conveyor belt fixed

coordinate system).

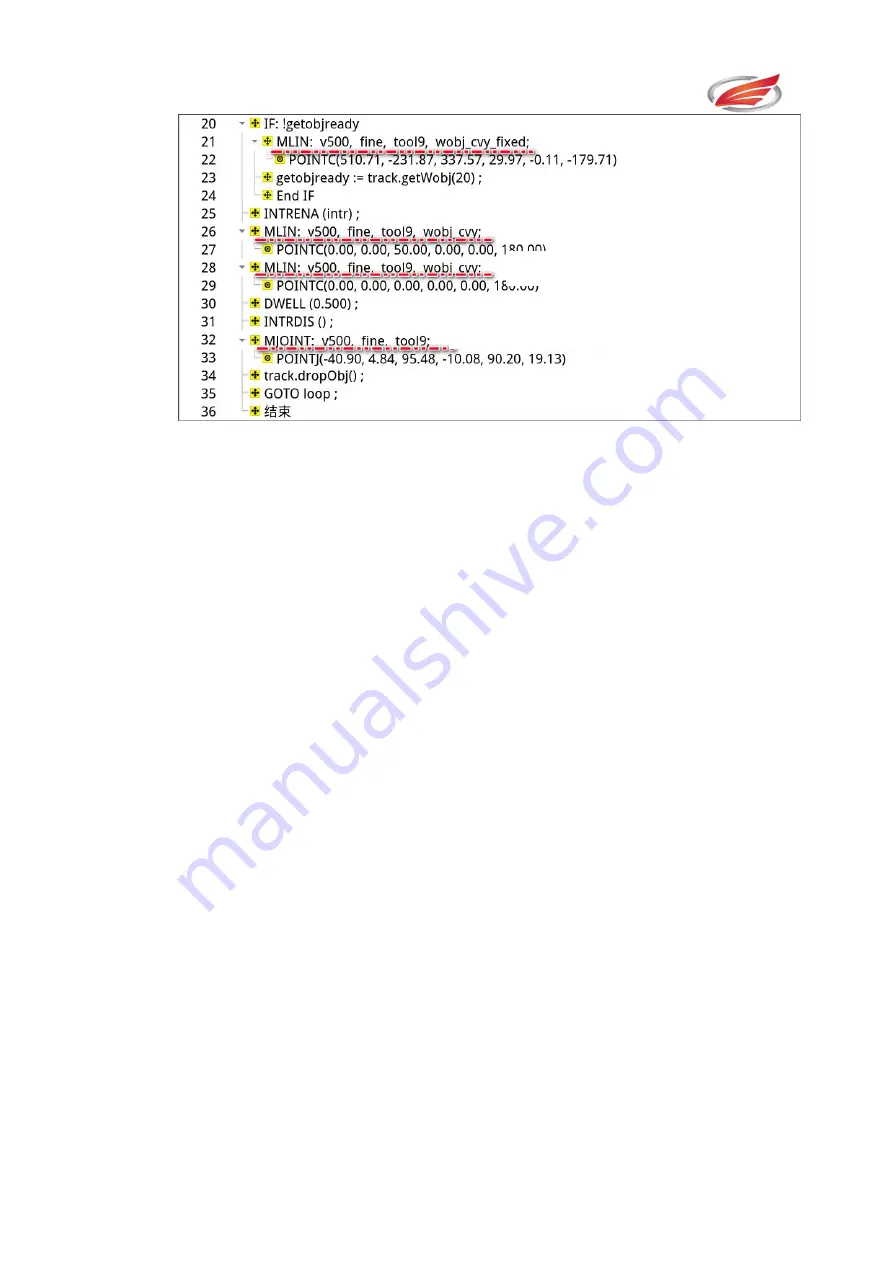

Line 23: the program will remain blocked on this line until the data of the tracking target

can be successfully acquired.

Line 25: opening of the interrupt trigger.

Line 26: Position 3, tracking workpiece point. The robot will move to a height of 50 mm

from the workpiece gripping point.

At the same time the attitude is adjusted to the tool vertical downwards, three values

after POINTC (0, 0, 180)

Line 28: Position 4, gripping workpiece point. The robot moves to the gripping position

of the workpiece, again with the tool vertical down attitude.

Line 30: Hold tracking for 0.5 seconds.

An IO open/close command can be added above this line of code to control the tool

suction/clamping of the workpiece.

Position 2: Robot waiting position

Position 3: Tracking workpiece points

Position 4: Grabbing workpiece points

Position 5: Workpiece placement point