32

REFILLING WITH SALT

If the conditioner/refiner uses all the salt before more is

added, hard water will result. Lift the brine tank lid and

check the salt level frequently. The remote can also be

used to monitor salt. It has an optional display, on the

conditioner/refiner status screen, of the estimated num-

ber of days until salt is depleted (“Out of salt in X

days”). The conditioner/refiner can also be pro-

grammed to display a Low Salt Alarm a certain number

of days before salt is estimated to run out (See Page

12).

Be sure that the brinewell cover is on when adding salt.

After adding and leveling salt, always set the salt level

on the electronic controller, as described on Page 12.

NOTE:

In humid areas it is best to keep the salt level

less than half full and refill more often.

RECOMMENDED SALT:

Cube, pellet, coarse solar,

etc., water conditioner salt is recommended. This type

of salt is high purity evaporated crystals, sometimes

formed and pressed into briquets. It has less than 1%

insoluble (not dissolvable in water) impurities. Clean,

high grade rock salts are acceptable, but may require

frequent brine tank cleaning to remove the “sludge”

residue (insolubles) collecting at the bottom of the tank.

POTASSIUM CHLORIDE:

If you choose potassium

chloride (KCl) salt as a regenerant:

1) Make sure “Salt type” on the electronic control is set

to “KCl”, as shown on Page 12.

2) Place only one bag of potassium chloride (KCl) into

your conditioner/refiner at a time. The salt storage

tank should never contain more than 25 kg of KCl.

SALT NOT RECOMMENDED:

Rock salt high in impuri-

ties, block, granulated, table, ice melting, or ice cream

making salts, etc., are not recommended.

SALT WITH IRON REMOVING ADDITIVE:

Some salts

have an additive to help a water conditioner/refiner han-

dle iron in the water supply. Although this may help

keep the resin bed clean, it may also release corrosive

fumes that will weaken and shorten the life of some

EcoWater Systems conditioner/refiner electronic parts.

Iron Out salt is safe to use on two-tank models.

ECOWATER

S Y S T E M S

Service Information

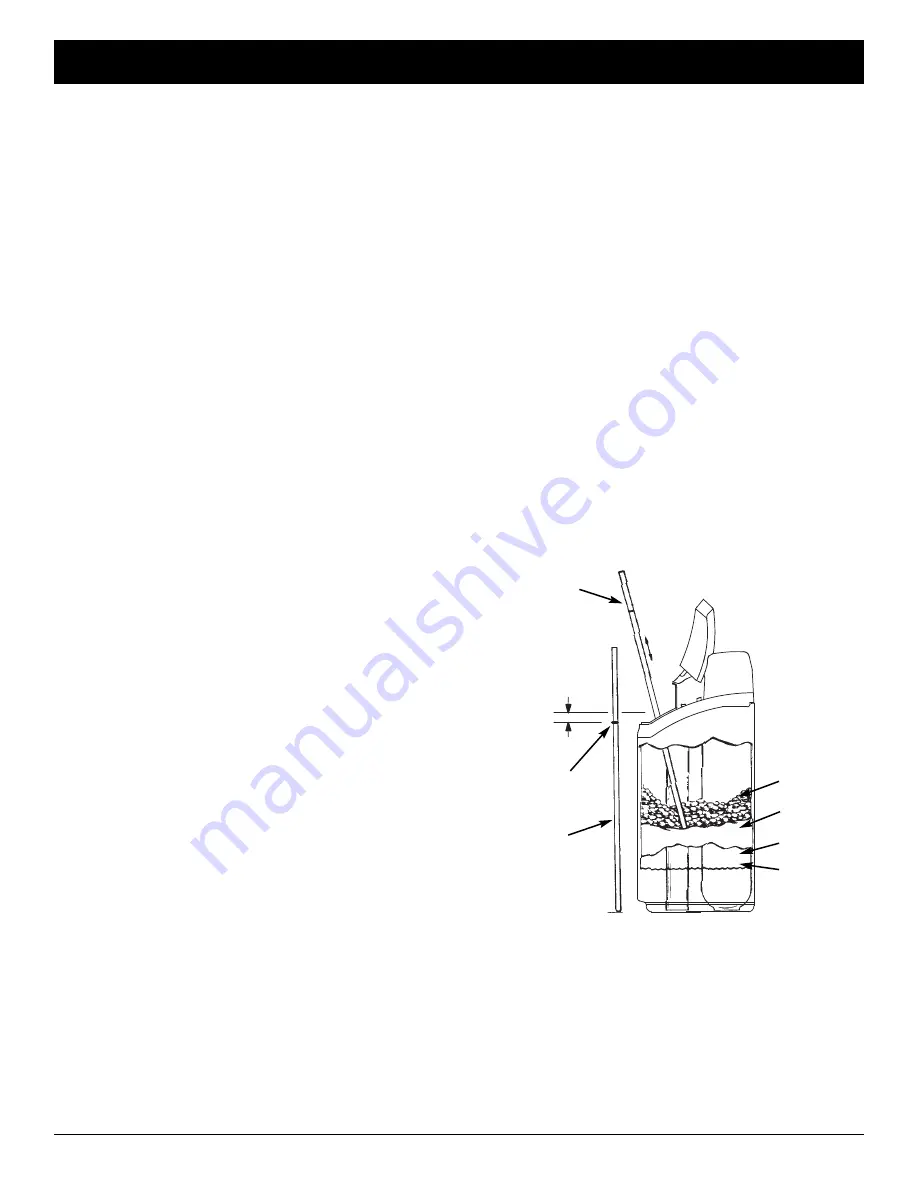

BREAKING A SALT BRIDGE

Sometimes a hard crust or salt “bridge” forms in the

brine tank. This is usually caused by high humidity or

the wrong kind of salt. When the salt bridges, an empty

space forms between the water and the salt. Then salt

will not dissolve in the water to make brine. Without

brine, the resin bed is not recharged and hard water will

result.

If the storage tank is full of salt, it is difficult to tell

whether there is a salt bridge. A bridge may be under-

neath loose salt. The following is the best way to check

for a salt bridge:

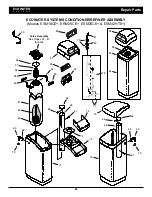

Salt should be loose all the way to the bottom of the

tank. Hold a broom handle, or like tool, up to the condi-

tioner/refiner, as shown in Figure 133. Make a pencil

mark on the handle 3 - 5 cm below the top of the rim.

Then, carefully push it straight down into the salt. If a

hard object is felt before the pencil mark is even with

the top, it is most likely a salt bridge. Carefully push

into the bridge in several places to break it.

Do not try

to break the salt bridge by pounding on the outside

of the salt tank. You may damage the tank.

FIG. 133

3 - 5 cm

Pencil Mark

Broom

Handle

Push tool into

salt bridge

to break

Water Level

Empty Space

Salt Bridge

Salt