6

7. CONNECT INLET & OUTLET PLUMBING

a. SOLDERED COPPER

(1) Thoroughly clean and flux all joints.

(2) Pull the plastic “C'' clips and remove the inlet and outlet

tubes from the valve. Remove o-rings from the tubes.

DO

NOT solder with tubes in the valve.

Soldering heat will

damage the valve.

NOTE:

If installing a ground as shown in Figure 4A, place

ground clamps on copper tubes before soldering (See Step

7a).

(3) Make all solder connections. Be sure to keep fittings fully

together, and pipes square and straight.

b. THREADED PIPE

(1) Apply pipe joint compound to all outside pipe threads.

(2) Tighten all threaded joints.

(3) If soldering to the inlet and outlet tubes, observe Step 7a

above.

c. CPVC PLASTIC PIPE

(1) Clean, prime and cement all joints, following the manufac-

turer's instructions supplied with the plastic pipe and fittings.

(2) If soldering to the inlet and outlet tubes, observe Step 7a

above.

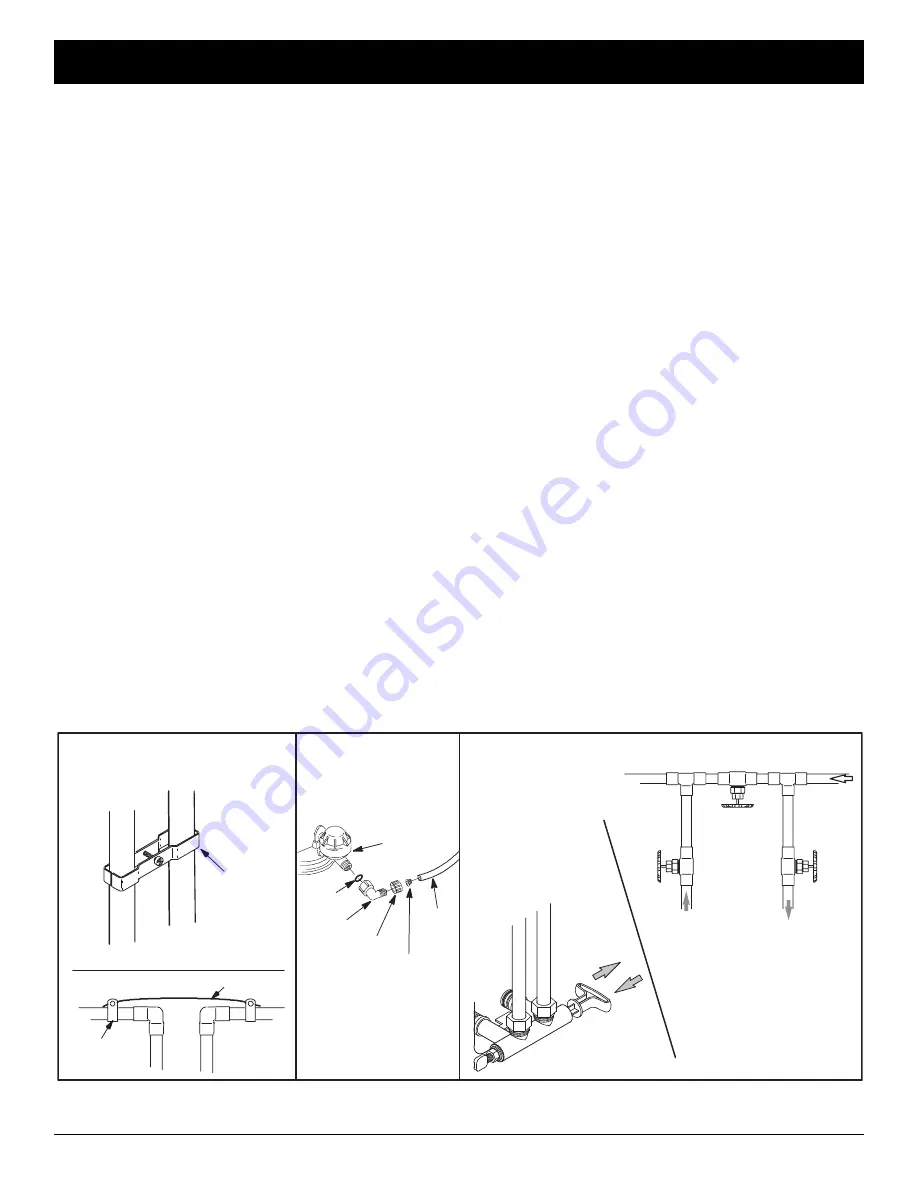

8. COLD WATER PIPE GROUNDING

The house cold water pipe (metal only) is often used as a

ground for the house electrical system. The 3-valve bypass

type of installation, shown in Figure 1, will maintain ground

continuity. If you use the plastic bypass, continuity is broken.

To restore the ground, do either step

8a

or

8b

following.

a

. Install the EcoWater Systems ground clamp kit (not includ-

ed) across the inlet and outlet copper pipes (See Figure 4A).

b

. Install a #4 copper wire across the removed section of

main water pipe, securely clamping at both ends (See Figure

4B) – parts not included.

9. INSTALL VALVE DRAIN HOSE

NOTE:

See valve drain options on Page 4.

a

. Elevating the drain hose may cause back pressure that

could reduce the brine draw during recharge. If raising the

drain line overhead is required to get to the drain point, meas-

ure the inlet water pressure to the conditioner/refiner first. For

inlet pressures between 1.4 and 3.4 bar, do not raise higher

than 2 meters above the floor. For inlet pressure above 3.4

bar, the drain line may be raised to a maximum height of 3

meters.

b

. Connect a length of 1/2" I.D. hose (check codes) to the

valve drain elbow, on the controller. Use a hose clamp to

hold the hose in place. Route the hose out through the notch

in the back of the top cover.

c

. Run the hose to the floor drain, and as typically shown in

Figure 1, tie or wire the end to a brick or other heavy object.

This will prevent “whipping” during recharges. Be sure to pro-

vide a 4 cm minimum air gap, to prevent possible sewer water

backup.

10. INSTALL BRINE TANK OVERFLOW

HOSE

a

. Connect a length of 1/2" I. D. hose to the brine tank over-

flow elbow and secure in place with a hose clamp.

b

. Run the hose to the floor drain, or other suitable drain point

no higher than the drain fitting

on the tank. If the tank

overfills with water, the excess water flows to the drain point.

11. On Two-tank models,

connect the brine tubing

to the nozzle and venturi housing.

FIG. 4

FIG. 5

FIG. 6

ECOWATER

S Y S T E M S

Installation

ground wire

clamp (2)

nozzle &

venturi

o--ring

elbow

Note: To ease brine tubing con-

nection, use the elbow and o--ring

seal as shown. Lubricate the o--

ring and insert into the elbow. Turn

the elbow on and tighten. Then,

back--off up to one turn, as need-

ed.

B

A

3 -- Valve Bypass

OUTLET

VALVE

INLET

VALVE

BYPASS

VALVE

to conditioner

from conditioner

EcoWater Systems

Bypass Valve

D

for

SERVICE:

-- Open

the

inlet

and

outlet

valves.

-- Close

the

bypass valve.

D

for

BYPASS:

-- Close

the

inlet

and

outlet

valves.

-- Open

the

bypass valve.

PUSH

IN

for

bypass

PULL

OUT

for

service

nut--ferrule

screen

ground

clamp

brine

tubing