Adjustments 27

1. Shut down the system and cut off electrical power by switching the Main Power

Disconnect to the Off position.

2. Supporting the seal head in the up position, loosen the four set screws for the

head return cylinder. Gently lower the seal head to rest on the lower seal pads.

3. With the seal head resting on the lower pads, shim up the film clamps so that the

inserts are resting on the lower pads. Make sure there are no air gaps, and then

tighten the head casting bolts.

4. Adjust magnets. (See Electromagnet Position Adjustment above.)

5. Go to the rear of the L-sealer. Make sure the head cylinder is straight from front

to back. Pull the air cylinder bracket the full length of the air cylinder. Tighten the

5

/

16

-inch set screws.

6. Cycle the seal head up and down. Adjust set screws on head return cylinders for

proper head speed and cushion.

L-Sealer Timers and Temperature Controls

Check dwell and conveyor-run timing, and temperature of front and side seals after

making adjustments or after performing maintenance, such as replacing seal pads,

cutting rules or hot knife inserts. Adjust as required using the adjustment provided

through the L-Sealer control panel.

L-Sealer Timer Controls

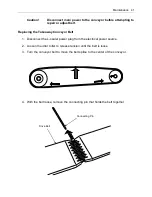

Each of the speed control timers for the L-sealer for the dwell and conveyor have an

adjustable potentiometer in the lower-left corner and a mode selector in the lower-right

corner. (See the illustration above.) Use a small screwdriver to turn pots in either

direction as required.

0

1

2

3

4

5

POWER

OUT

MODE

AT11DN

RUN

A

0

1

2

3

4

5

POWER

OUT

MODE

AT11DN

RUN

A

DWELL

CONVEYOR

sec.

sec.

Speed Pot

Mode Selector

Speed Pot

Mode Selector

Содержание Combination EC Series

Страница 1: ...EC Combination Series Semi Automatic L Sealer Tunnel User Guide EC2016T EC2016TK EC2028T EC2028TK ...

Страница 2: ......

Страница 4: ......

Страница 73: ...Appendix A Electrical Schematic 73 Electrical Schematic L Sealer ...

Страница 81: ......