21

Dramm Autofog MLVH-10A Manual

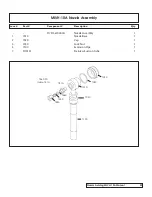

1. The spray pattern exits the nozzle in short bursts – it

should exit as a steady stream.

A. The nozzle cap is not secure or properly lined up.

Screw it on completely and then turn the cap

counter clockwise so the two check marks on the

nozzle line up. Check the nozzle calibration for

45cc/minute output rate. See diagram below.

B. The nozzle cap has an O-Ring inside which may

be damaged. Replace the O-Ring if it is cracked,

broken or in some way damaged.

C. Inspect the suction tube for clogging or damage.

To remove the suction tube from the nozzle first

loosen the nut that holds the tube to the nozzle.

Now, pull the tube out of the nozzle. Notice

the metal sleeve on the tube, inspect it carefully.

In most cases the sleeve must be replaced if it is

damaged, dented, bent or cracked.

DO NOT OVER TIGHTEN NUT

D. The nozzle and/or solution tank may be clogged

with chemical residue. Soak the nozzle

overnight, then clean the inside of the nozzle.

E. The suction tube may be clogged or damaged. With a

gloved hand, cover the nozzle tip. This reverses the

flow of air and blows the suction tube clean of any

debris. Remove and clean the tube or replace it if

necessary. See the diagram below.

F. The suction tube is above the surface of the solution in

the tank. Make sure the suction tube is pushed down

completely.

G. The filter at the bottom of the stainless steel suction

tube is clogged and needs cleaning. Inspect the entire

suction tube for clogging.

Continued on the next page...

Suction Tube

Nut

Sleeve

Troubleshooting

NOTE:

ALWAYS

wear a glove when covering the nozzle.

Nozzle Cap

Checkmark

Checkmark

Suction Tube

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

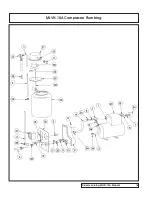

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...