The Dramm Autofog applys chemicals under the

low-volume (LV) principle. This means that the same

amount of active chemical is applied to a given area,

but the chemical is diluted into reduced amounts of

water. Because LV application is very efficient, many

users have found that lower volumes of chemical can

be used with the same results.

The Mini Autofog MLVH-10A will require a

minimum of 2 liters of water and the chemical to treat

5,000 square feet. If less than 5,000 square feet is

treated, a minimum of 2 liters of water is still used.

The specially designed solution tank and agitator

prevents concentrated chemicals from precipitating.

According to conventional high-volume (HV) spraying

methods, approximately 20 gallons of water (diluent)

plus the chemical is needed to treat 5,000 square feet.

LV application is only possible when extremely fine

particles are produced. The patented nozzle design of

the Mini Autofog MLVH-10A produces particles which

will range in size from .5 to 10 microns in diameter. Air

enters the nozzle from the oil-less compressor and

then exits the nozzle at super sonic speeds. This

movement of air creates a venturi that draws solution

from the chemical tank. As the solution exits the

nozzle it is micronized into billions of tiny particles.

The micronized chemical particles stay suspended for

up to 6 hours and are distributed by horizontal airflow

fans (HAF) and natural air currents.

The Mini Autofog MLVH-10A features manual

starting and a timer for automatic shut-down. Other

features include a safety valve on the compressor to

release any abnormal pressure build-up. The motor

which drives the compressor is supplied with a

grounded electrical cord set and is protected from

overheating with a thermal fuse that disconnects

power to the entire sprayer. The Mini Autofog MLVH-

10A now has a redesigned frame and handle to ease in

its transportation in small greenhouses and storage

facilities.

How Does My Autofog MLVH-10A Work?

7

Dramm Autofog MLVH-10A Manual

Note: Dramm offers an instructional video on our website. Please watch this before using your machine.

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

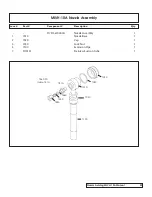

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

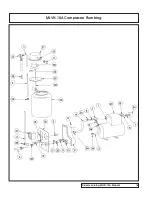

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...