Dramm Autofog MLVH-10A Manual

6

1. Attach handle to side of machine opposite control

panel using four 1/4- 20 x 3/4 hex bolts. Tighten.

2. Place lower nozzle stand over studs showing through

red compressor unit cover. Adjusting knob should face

control panel. Place lockwashers and nuts on studs and

tighten.

3. Insert the nozzle stand into the nozzle stand tube with

the nozzle bracket facing away from the control panel

end. Adjust the height of the nozzle stand as necessary.

Tighten the black height adjustment knob.

4. Place the solution tank into the circular tank holder.

Rotate the tank so that the small suction hole faces the

front of the machine (the control panel end is the back

of the machine).

5. Secure the nozzle onto the nozzle stand. Insert the

suction tube into the solution tank. Check that the

suction tube reaches the bottom of the tank (there is a

slight depression in the bottom of the tank where the

suction tube should rest). Place the agitator back into

the solution tank and secure with the turn tabs.

6. On the control panel, insert air hose into the press-fit

connection marked AIR TO NOZZLE. On the nozzle,

insert air hose the same way.\

7. Plug the agitator power cord into the control panel and

connect the main power cord into a 110 volt power

source.

8. The unit is ready to spray. But before you start

spraying, read this manual thoroughly and follow all

E.P.A. Guidelines.

9. Before you spray for the first time, test the MLVH-10A

with water. Pour a small amount of clear water (about

1 liter) into the solution tank. Rotate the timer

clockwise. Spraying begins immediately. Observe the

quality of the spray pattern and pressure gauge

readings. If you have any questions, contact the Dramm

Corporation Service Department at 800-258-0848 or

920-684-0227.

List of tools needed:

• 7/16" Wrench

• 1/2" Open End Wrench

• 9/16" Open End Wrench

• Straight Blade Screwdriver

• MLVH-10A Assembly Diagram

• 1/2" Socket Wrench

Autofog MLVH-10A Assembly Instructions

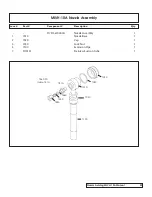

Nozzle Cap

Checkmark

Checkmark

Suction Tube

Securing Nut

x

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

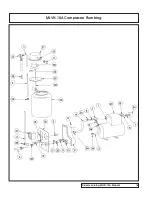

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...