The key to successful results with the MLVH-10A is

keeping the machine clean. There are only a few

steps involved, so it will be very easy.

Be sure to

clean the machine after every use.

1. Using warm water and a soft cloth wash:

A. The Solution tank

B. The Solution tank cover

C. The Agitator blades

D. The Suction tube

E. Spray clear water through nozzle

F. Wipe off the machine

2. Remove the nozzle from the MLVH-10A by

unscrewing the securing nut. Remove the nozzle

cap and wipe off any chemical residue. Always

handle the nozzle and cap with care, especially the

nozzle tip (see diagram below). Inspect the nozzle

cap O-ring for damage or wear.

NOTE:

This procedure is necessary after every application

of wettable powder solutions. Be sure to remove

the nozzle cap and clean the nozzle.

3. After every 25 hours of use, be sure to clean the air

filter (Located under the compressor housing, on

top of the compressor). Brush any excess debris off

the filter and then rinse with warm water. Use a

mild detergent if necessary. ALWAYS let the filter

air dry completely before reinstalling.

NOTE:

The air filter will contain particles of the chemicals

you have been applying. When cleaning the filter

follow all EPA Guidelines for the handling and

disposal of chemicals.

4. Store the MLVH-10A where it is away from

excessive moisture, children and unauthorized

personnel. If you are storing the MLVH-10A for a

long period of time, cover the equipment with a

plastic sheet.

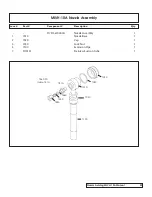

Compressor Air Filter

Air Filter

Air Filter Housing

REPLACE FILTER ONCE A YEAR OR AFTER

500 HOURS OF USE.

Cleaning & Maintenance

O-Ring

Nozzle Tip

Nozzle Cap

Nozzle

13

Dramm Autofog MLVH-10A Manual

A video showing the

cleaning procedure for

the MLVH is available on

our website.

Dramm offers an Annual Maintenance Kit (AMK) to keep your

AutoFOG in top shape. Contact us annually to order this kit.

A video showing the maintenance involved in the AMK is

available on our website.

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

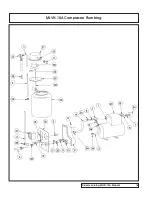

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...