Dramm Autofog MLVH-10A Manual

5

WARNING

• The Dramm Autofog MLVH-10A is a low-volume

application machine that applies

Hazardous

Chemicals

in concentrated solutions.

Care

and

Logic

must be adhered to. The solution

particle size is very small (0.5 microns to 10.0

microns).

Beware of inhalation.

•

Follow EPA Guidleines

for application of

chemicals.

•

Wear Protective Clothing

, gas mask, hood

gloves and boots when mixing chemicals, pouring

chemicals into the tank and when applying

chemicals.

•

Ensure area to be treated is securely

closed

- with no vents open.

•

Ensure That No humans or Pets Are In

The Area To Be Treated

- death from

chemicals could occur!

• After the machine has been turned on, chemical

application begins. Exit the area immediately.

Secure or lock the enclosure. Post “

Do Not

Enter

” hazard signs.

The Deadly Chemical

Vapor Will Not be Visible!

It is your

responsibility to ensure no one can enter the

enclosure for at least 6 hours after the machine has

stopped applying chemical.

•

Before Re-Entry, Air Must Be Changed

By Venting.

Follow all EPA Guidelines for re-

entry periods.

•

Do Not Use This Machine In An

Enclosure Where Vapors Can Enter

Any Type Of Air Vents.

Care should be

taken to ensure vapors can not reach buildings or

homes in close proximity to the enclosure being

treated.

•

After Use, Double Rinse The Chemical

Tank

and dispose of rinse water according to EPA

Guidelines. Clean the nozzle and suction line

thoroughly. Store the unit in a safe location away

from children and unauthorized personnel.

•

Mix Only The Amount of Chemical

Which Will Be Used

to treat the area.

Never - Keep - Store - Or Hold Over

Unused Chemical Solution.

• Your machine is labeled 110 volt - single phase, 220

volt - single phase or 220 volt - 3 phase.

Be Sure

To Connect Your Machine To The

Correct Voltage Receptacle.

Contact

your electrician for accurate voltage/phase

readings if necessary.

•

Exercise Accepted Saftey Procedures

when using electricity.

The Dramm Mini Autofog MLVH-10A sprays dangerous toxic chemicals. Please read and

understand the following safety precautions before operating your Autofog. Failure to follow these

instructions may result in serious injury or death.

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

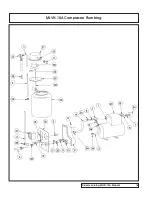

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

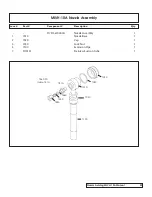

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...