The MLVH-10A should be allowed to run for a half

hour after all chemical has been expelled into the

air. See the chart below for approximate amount

of time it takes to expel chemicals. These times

were compiled with clear water - the expulsion

time time may exceed these guidelines when

mixed with chemicals.

Times may vary due to the consistency of solution

being sprayed. Thicker solutions

may take longer to discharge.

1. Plug the AutoFog into the appropriate power

source.

2. Set the clock to the correct time. The timer is a 24

hour timer for accuracy between day and night.

3. Determine the spray starting time and stopping

time.

4. Flip ALL of the pins between the starting and

stopping time to the OUTSIDE. (see photo below)

5. The AutoFog will run only during the time that the

pins are flipped to the outside of the clock. DO

NOT FLIP THE START TIME AND STOP TIME

ONLY. Each pin represents 15 minutes of time.

6. The AutoFog is now ready and will begin fogging at

the appropriate time. Make sure the treatment

area is secure and will be empty of all personnel at

that time.

NOTE:

Remember to add a half hour to the spraying time

when setting the timer.

1. Vacate the treatment area, secure all entry ways

and post hazard signs.

2. Prepare the chemical solution. See page 10 for

dilution rate details. Be sure that the solution is

free of clumps of chemical that may clog the

nozzle. Use a whisk or blender to make a smooth

paste of wettable powder solutions. Check that

the suction tube screen is in place in the tank.

Pour the solution through the large solution

strainer/ funnel assembly to eliminate any unmixed

chemical or debris.

3. Plug in the main power cord. Notice the power

lamp illuminated on the control panel.

4. Set the timer. Turn the dial past, then return to

the desired operation time. The MLVH-10A will

begin to spray, vacate the treatment area

immediately.

5. If horizontal airflow fans are used, allow them to

run a half hour longer than the predetermined

spray time.

6. In order to allow all of the spray particles to settle,

do not re-enter the treatment area for a minimum

of 6 hours after the MLVH-10A has completed its

operation. Keep the structure airtight. However, if

it is necessary to enter the treatment area during

application, only do so in a full spray suit, boots,

gloves, hood and respirator.

7. After spraying, ventilate the treatment area with

fresh air and clean the MLVH-10A thoroughly.

Follow all EPA Guidelines for re-entry.

DISCHARGE TIMES FOR MLVH-10A

Clear Water

Time

1.0 liter 30 minutes

2.0 liters 1 hour

3.0 liters 1.5 hours

4.0 liters 2.0 hours

5.0 liters 2.5 hours

6.0 liters 3.0 hours

7.0 liters 3.5 hours

Dramm Autofog MLVH-10A Manual

12

Spraying Procedure

Timer Settings

How To Set The Timer

A video on programming

your timer is available on

our website.

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

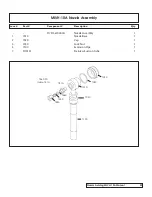

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

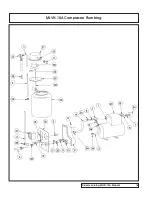

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...