Precautions / Pre-Operation Checklist

D. Cold weather operation: When the temperature falls

below 32°F run the compressor in a warm environment

before placing the MLVH-10A assembly in the area to

be treated. The bearing grease may harden in very cold

temperatures causing the compressor to not preform

properly. Unless absolutely necessary, do not operate

the MLVH-10A in sub 25°F weather.

E.

You will get an accurate output volume if

the nozzle cap is closed completely and

then returned to match the red check

marks. See diagram below.

NOTE:

Output volume will vary 2.5 - 3.0 cc/min. for each

notch in the nozzle cap.

•Clockwise: Output INCREASES

•Counterclockwise: Output DECREASES

NOTE:

Check the O-ring located inside the nozzle cap for wear

or damage. Replace if necessary

Dramm Autofog MLVH-10A Manual

8

A. For the most effective performance, the treatment area

must be air tight. Take time to repair any broken glass,

torn poly and gaps or openings in vents and door

frames.

B. The entire treatment area should be vacant. No

humans or pets should be present.

C. It is recommended that the application process take

place at the end of the day. Secure the treatment area

and post hazard signs

before

spraying.

D. Avoid spraying when the temperature is over 85°F in

the treatment area or when relative humidity exceeds

85%.

E. When utilizing horizontal airflow fans (HAF), run them

for 1/2 hour longer than actual spraying time.

F. Follow all EPA Guidelines regarding the application of

chemicals.

A. Test run the MLVH-10A with clear water for 1-2

minutes. Observe the spray quality.

B. The discharge volume rate of clean water is

approximately 45 cc / minute. When testing the

unit, pull the suction hose out of the solution tank

and place it in a graduated cylinder (fill it with 90

cc of clean water). The cylinder should be empty

after a 2 minute test run. Be sure to check the

discharge volume rate regularly to assure best

results.

C. Observe the operating pressure. The gauge will

read 14-23 PSI. NOTE: Check for leaks in the

piping when the pressure is too low. Eliminate

clogs if the pressure is too high. Pressure readings

may vary from location to location. Small

differences are inconsequential.

Compressor/Sprayer

Treatment Area

WARNING:

The standard model Autofog uses a

nozzle that is manufactured with brass components.

The use of oxidizers will damage this nozzle

within several applications.

If you plan to use oxidizers in your Autofog,

CONTACT DRAMM BEFORE THE FIRST USE OF YOUR

MACHINE

to purchase a stainless steel nozzle at a

reduced cost. After your machine has been used,

Dramm cannot accept the original nozzle

back for credit.

Содержание Autofog MLVH-10A

Страница 1: ...AUTOFOG MLVH 10A Owners Manual...

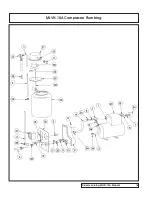

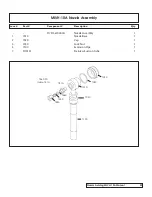

Страница 12: ...Dramm Autofog MLVH 10A Manual 14 MLVH 10A Assembly Diagram...

Страница 14: ...Dramm Autofog MLVH 10A Manual 16 MLVH 10A Compressor Plumbing...

Страница 15: ...MLVH 10A Compressor Plumbing Parts List 17 Dramm Autofog MLVH 10A Manual...

Страница 16: ...MLVH 10A Compressor Diagram Dramm Autofog MLVH 10A Manual 18...

Страница 17: ...MLVH 10A Compressor Parts List 19 Dramm Autofog MLVH 10A Manual...