MINNY

MINNY

MINNY

MINNY

32

32

32

32

23.5

23.5

23.5

23.5

O

O

O

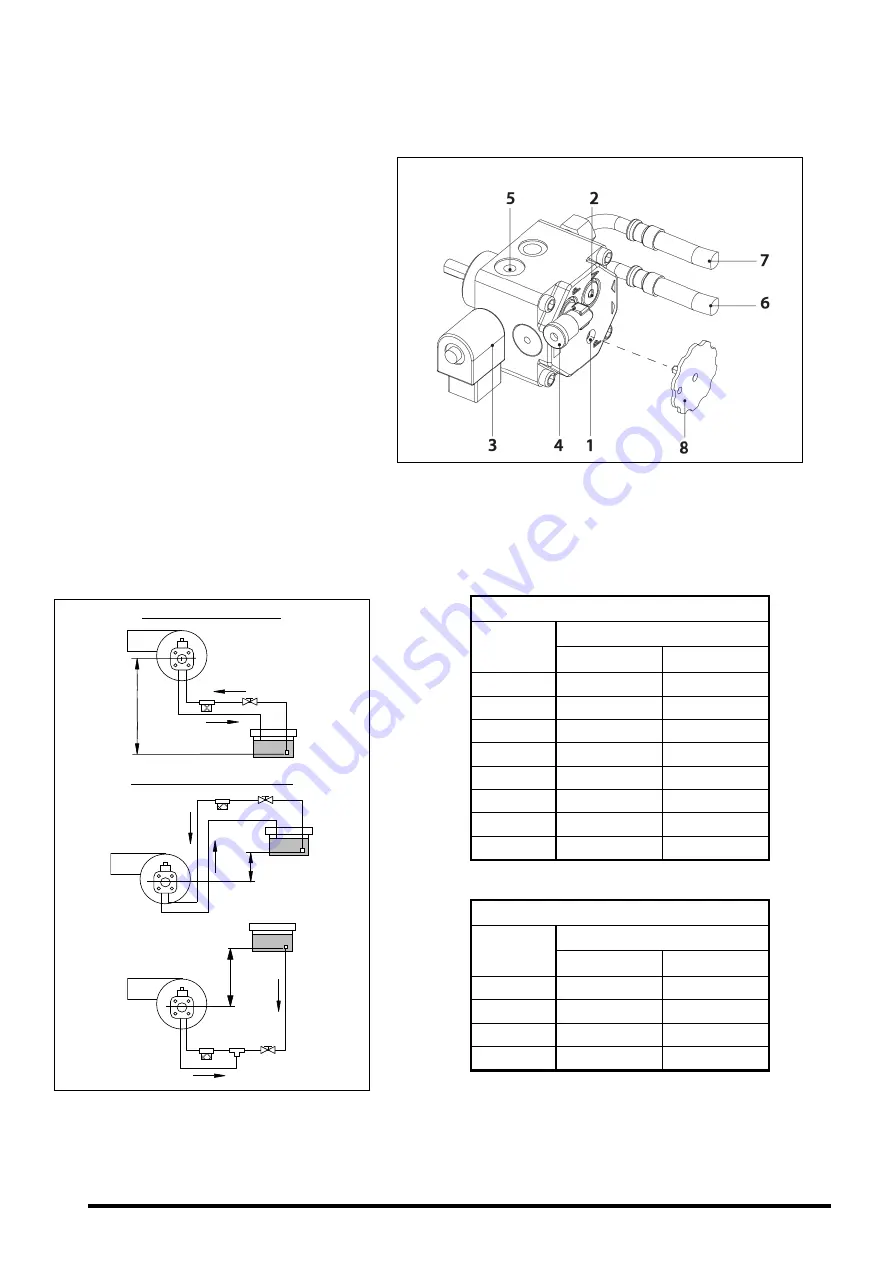

Oil pressure adjustment

il pressure adjustment

il pressure adjustment

il pressure adjustment

To adjust the oil pump pressure, turn the screw

(1)

(1)

(1)

(1)

clockwise to increase the pressure, and

anticlockwise to decrease it.

1 - Pressure adjustment.

2 - Vacuum gauge point.

3 - Valve.

4 - Manometer point.

5 - Nozzle outlet.

6 - Return.

7 - Intake.

8 – Pressure regulation.

23.6

23.6

23.6

23.6

Oil supply piping diagrams

Oil supply piping diagrams

Oil supply piping diagrams

Oil supply piping diagrams

The diagrams and tables below correspond to installations without reductions and with a perfect

hydraulic seal. It is recommended to use copper pipes. A pressure drop of 0.4 bar (30 cmHg) must

not be exceeded.

Intake installation

Intake installation

Intake installation

Intake installation

H

H

H

H----

Pipe length

Pipe length

Pipe length

Pipe length

(m)

∅

int 8 mm.

∅

int 10 mm.

0,0

34

82

0,5

30

72

1,0

25

62

1,5

21

52

2,0

17

42

2,5

13

32

3,0

9

21

3,5

6

16

Charging installation

Charging installation

Charging installation

Charging installation

H

H

H

H+

+

+

+

Pipe length

Pipe length

Pipe length

Pipe length

(m)

∅

int 8 mm.

∅

int 10 mm.

0,5

36

82

1,0

42

90

1,5

46

100

2,0

50

100

WARNING: Check periodically the flexible pipes conditions. Using kerosene, they have

WARNING: Check periodically the flexible pipes conditions. Using kerosene, they have

WARNING: Check periodically the flexible pipes conditions. Using kerosene, they have

WARNING: Check periodically the flexible pipes conditions. Using kerosene, they have to be

to be

to be

to be

replaced at least every 2 years

replaced at least every 2 years

replaced at least every 2 years

replaced at least every 2 years

Intake installation

Intake installation

Intake installation

Intake installation

H-

Charging installation

Charging installation

Charging installation

Charging installation

H+

H+

DANFOSS

DANFOSS

DANFOSS

DANFOSS ---- MOD. BFP 21 L3

MOD. BFP 21 L3

MOD. BFP 21 L3

MOD. BFP 21 L3