35

MAINTENANCE

REPLACING SAW GUIDE AND BACK‐UP INSERTS

These instructions can be used to replace

the saw guide inserts and back‐up rollers or

inserts on both saw guide arms.

The band drive motor must NOT be running

when replacing saw guide and back‐up

inserts or rollers.

1.

Loosen the insert adjustment screw on each saw

guide arm. Then: (a) remove the left saw band

guard (if necessary); (b) remove the adjustment

screw being very careful not to drop or lose the

insert, screw and washers; (c) loosen the socket cap

screw from the rear side of the saw guide arms and

remove the rear inserts.

2.

Thoroughly clean the saw guide arm and inserts

area. Then: (a) check the back‐up rollers or inserts

for wear and replace them in needed.

3.

Install the new fixed insert and tighten the screw.

Then: (a) thread the adjusting screw inward part

way; (b) install the adjustable insert; (c) tighten the

adjustment screw; (d) replace the left saw band

guard (if removed).

BAND DRIVE/BRUSH BELT REPLACEMENT

1.

To change the band drive belt, open the right band

wheel door. Then: (a) undo the guard clip and

remove the screws; (b) located in the rear of the

machine between the band drive motor and the

gearbox, turn adjustment knob counterclockwise to

relax belt tension; (c) remove the old belt and install

the new belt by stretching the belt over the desired

speed range set of pulley’s.

2.

Turn adjustment knob clockwise to tension the belt.

There should be very little deflection at the center

span of the belt.

3.

Flip the cover back up and engage the clip and

install the screws.

HYDRAULIC SYSTEM

1.

The machine’s hydraulic reservoir capacity depends

on machine model. Check the oil level daily by

referring to the side gauge located on the left side

of the machine behind the control console.

2.

Before changing the hydraulic oil: (a) lower the saw

head completely; (b) push the hydraulic stop button;

(c) place a container of sufficient capacity under the

drain port; (d) remove the drain plug; (e) allow the

reservoir to drain completely.

3.

Drain, clean and refill the reservoir. Change oil after

the first three months, and every six months

thereafter. Clean the suction strainer and filter

opening screen when necessary. Use high quality

hydraulic oil, type ISO‐VG 46.

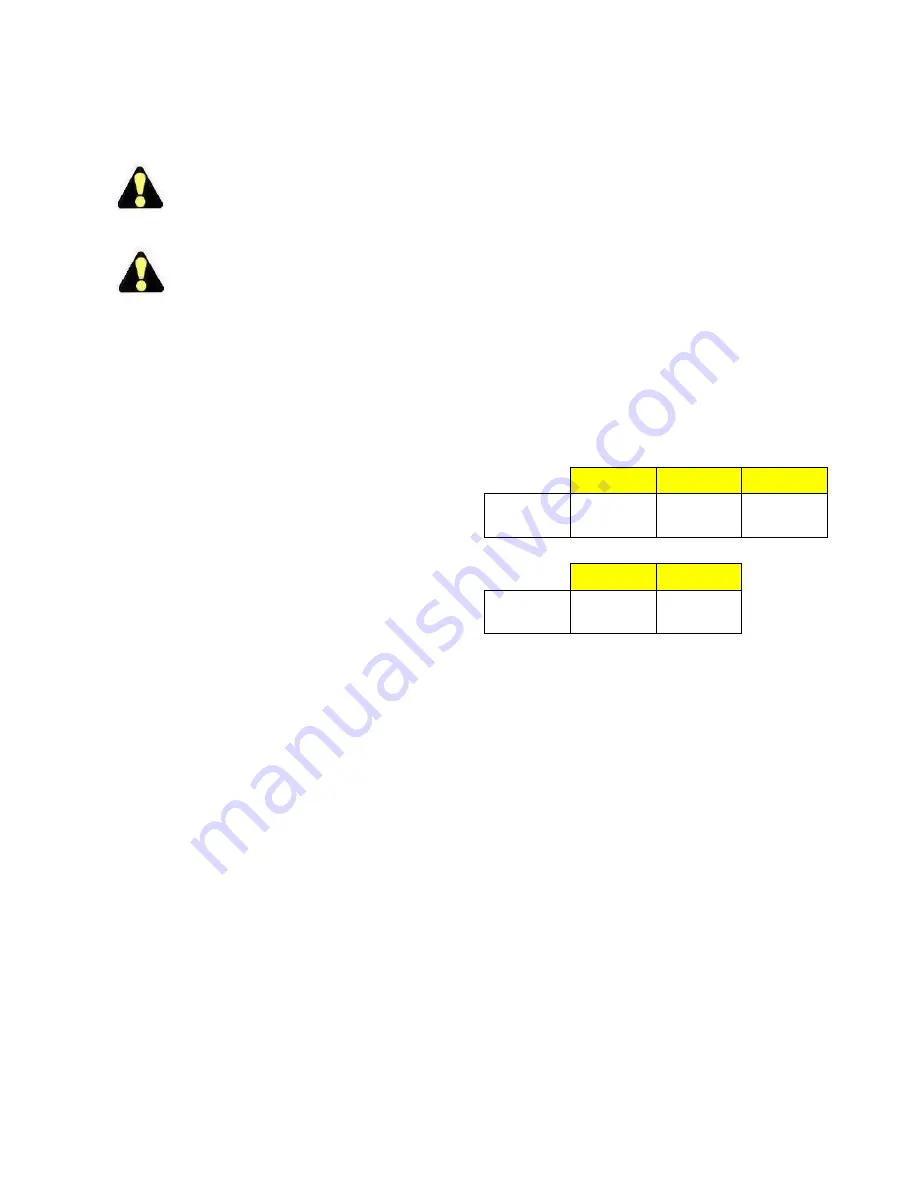

System pressure

1.

Hydraulic system pressure is correctly set at the

factory and should not require adjustment for a

considerable period of time.

C‐3028NC

C‐4033NC

C‐420NC

System

pressure

30 bar

30 bar

40 bar

C‐5650NC

C‐560NC

System

pressure

40 bar

45 bar

COOLANT SYSTEM

1.

The machine’s coolant reservoir capacity depends

on machine model. A reservoir level sight gauge is

located at the machine’s right front side.

2.

Check the coolant often for signs of contamination

or breakdown. The reservoir and coolant system

should be drained and cleaned thoroughly when

the cutting fluid becomes undesirable for further

use. If another type of coolant is to be used, the

entire system must be flushed using DoALL Kleen

Flush.

3.

To thoroughly clean the reservoir section below the

conveyor trough, removal of the trough will be

necessary.

4.

Fill the reservoir with coolant through the conveyor

screw until the

red

marking line in the side gauge.

Содержание C-3028NC Boxed

Страница 2: ......

Страница 3: ......

Страница 11: ...6 MACHINE DIMENSIONS Continued C 3028NC DIMENSIONS...

Страница 12: ...7 MACHINE DIMENSIONS Continued C 3028NC Boxed DIMENSIONS...

Страница 13: ...8 MACHINE DIMENSIONS Continued C 4033NC DIMENSIONS...

Страница 14: ...9 MACHINE DIMENSIONS Continued C 420NC DIMENSIONS...

Страница 15: ...10 MACHINE DIMENSIONS Continued C 420NC BOXED DIMENSIONS...

Страница 16: ...11 MACHINE DIMENSIONS Continued C 5650NC DIMENSIONS...

Страница 17: ...12 MACHINE DIMENSIONS Continued C 560NC DIMENSIONS...

Страница 18: ...13 MACHINE DIMENSIONS Continued C 6260NC DIMENSIONS...

Страница 19: ...14 MACHINE FEATURES...

Страница 39: ...34 LUBRICATION DIAGRAM...