For incremental encoders the Encoder Resolution is found

in either

5-70 Term 32/33 Pulses per Revolution

(24V HTL on

standard drive) or

17-11 Resolution (PPR)

(5V TTL on

MCB102 Option).

Generally the practical maximum limit of

30-83 Speed PID

Proportional Gain

is determined by the encoder resolution

and the feedback filter time but other factors in the

application might limit the

30-83 Speed PID Proportional

Gain

to a lower value.

To minimize the overshoot,

7-03 Speed PID Integral Time

could be set to approx. 2.5 sec. (varies with the

application).

7-04 Speed PID Differentiation Time

should be set to 0 until

everything else is tuned. If necessary finish the tuning by

experimenting with small increments of this setting.

3.4.3 Process PID Control

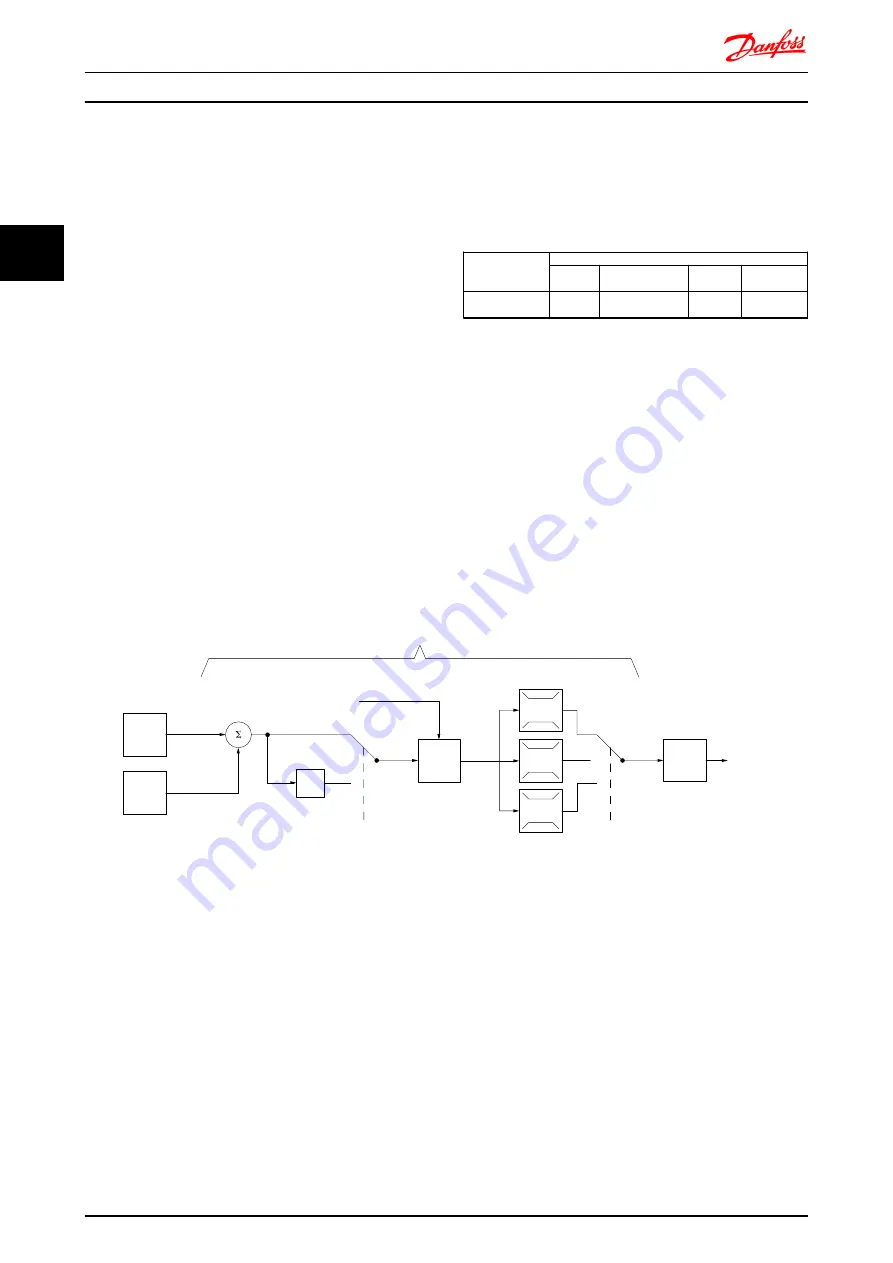

The Process PID Control can be used to control application

parameters that can be measured by a sensor (i.e.

pressure, temperature, flow) and be affected by the

connected motor through a pump, fan or otherwise.

The table shows the control configurations where the

Process Control is possible. When a Flux Vector motor

control principle is used, take care also to tune the Speed

Control PID parameters. Refer to the section about the

Control Structure to see where the Speed Control is active.

1-00 Configu-

ration Mode

1-01 Motor Control Principle

U/f

VVC

plus

Flux

Sensorless

Flux w/ enc.

feedb

[3] Process

N.A.

Process

Process &

Speed

Process &

Speed

NOTE

The Process Control PID will work under the default

parameter setting, but tuning the parameters is highly

recommended to optimise the application control

performance. The two Flux motor control principles are

specially dependant on proper Speed Control PID tuning

(prior to tuning the Process Control PID) to yield their full

potential.

P 7-30

normal/inverse

PID

P 7-38

*(-1)

Feed forward

Ref.

Handling

Feedback

Handling

% [unit]

% [unit]

%

[unit]

%

[speed]

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

Process PID

130BA178.10

_

+

0%

-100%

100%

0%

-100%

100%

Illustration 3.6 Process PID Control diagram

Introduction to FC 300

FC 300 Design Guide

32

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

3

3

Содержание VLT AutomationDrive

Страница 1: ...MAKING MODERN LIVING POSSIBLE Design Guide VLT AutomationDrive ...

Страница 280: ...www danfoss com drives MG33BD02 130R0301 MG33BD02 Rev 2011 03 29 ...

Страница 281: ......