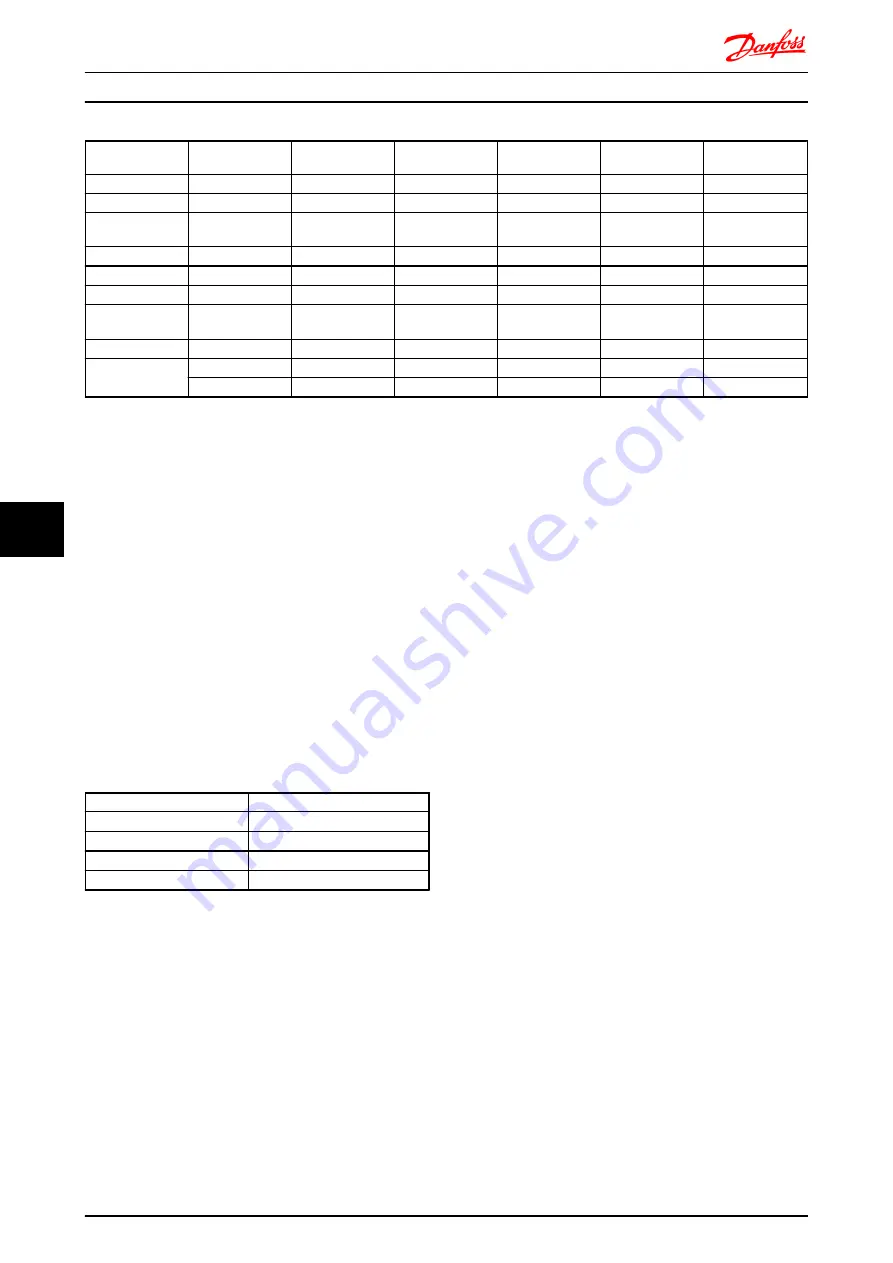

Frame Size

Power Size [kW]

Voltage [V]

1 cable [m]

2 cables [m]

3 cables [m]

4 cables [m]

A1, A2, A5

0.37-0.75

400

150

45

8

6

500

150

7

4

3

A2, A5

1.1-1.5

400

150

45

20

8

500

150

45

5

4

A2, A5

2.2-4

400

150

45

20

11

500

150

45

20

6

A3, A5

5.5-7.5

400

150

45

20

11

500

150

45

20

11

B1, B2, B3, B4,

C1, C2, C3, C4

11-75

400

150

75

50

37

500

150

75

50

37

Problems may arise at start and at low RPM values if motor sizes are widely different because small motors' relatively high

ohmic resistance in the stator calls for a higher voltage at start and at low RPM values.

The electronic thermal relay (ETR) of the frequency

converter cannot be used as motor protection for the

individual motor of systems with parallel-connected

motors. Provide further motor protection by e.g.

thermistors in each motor or individual thermal relays.

(Circuit breakers are not suitable as protection).

8.5.4 Motor Insulation

For motor cable lengths

≤

the maximum cable length

listed in the General Specifications tables the following

motor insulation ratings are recommended because the

peak voltage can be up to twice the DC link voltage, 2.8

times the mains voltage, due to transmission line effects in

the motor cable. If a motor has lower insulation rating it

recommended to use a du/dt or sine wave filter.

Nominal Mains Voltage

Motor Insulation

U

N

≤

420 V

Standard U

LL

= 1300V

420V < U

N

≤ 500 V

Reinforced U

LL

= 1600V

500V < U

N

≤ 600 V

Reinforced U

LL

= 1800V

600V < U

N

≤ 690 V

Reinforced U

LL

= 2000V

8.5.5 Motor Bearing Currents

All motors installed with FC 302 90 kW or higher power

drives should have NDE (Non-Drive End) insulated bearings

installed to eliminate circulating bearing currents. To

minimize DE (Drive End) bearing and shaft currents proper

grounding of the drive, motor, driven machine, and motor

to the driven machine is required.

Standard Mitigation Strategies:

1.

Use an insulated bearing

2.

Apply rigorous installation procedures

-

Ensure the motor and load motor are

aligned

-

Strictly follow the EMC Installation

guideline

-

Reinforce the PE so the high frequency

impedance is lower in the PE than the

input power leads

-

Provide a good high frequency

connection between the motor and the

frequency converter for instance by

screened cable which has a 360°

connection in the motor and the

frequency converter

-

Make sure that the impedance from

frequency converter to building ground

is lower that the grounding impedance

of the machine. This can be difficult for

pumps

-

Make a direct earth connection between

the motor and load motor

3.

Lower the IGBT switching frequency

4.

Modify the inverter waveform, 60° AVM vs.

SFAVM

5.

Install a shaft grounding system or use an

isolating coupling

6.

Apply conductive lubrication

7.

Use minimum speed settings if possible

8.

Try to ensure the line voltage is balanced to

ground. This can be difficult for IT, TT, TN-CS or

Grounded leg systems

9.

Use a dU/dt or sinus filter

Electrical Installation

FC 300 Design Guide

208

MG.33.BD.02 - VLT

®

is a registered Danfoss trademark

8

8

Содержание VLT AutomationDrive

Страница 1: ...MAKING MODERN LIVING POSSIBLE Design Guide VLT AutomationDrive ...

Страница 280: ...www danfoss com drives MG33BD02 130R0301 MG33BD02 Rev 2011 03 29 ...

Страница 281: ......